Processes,

procedures & technology

In order to manufacture series products costs-effectively and in the required quality, extensive know-how about processes, manufacturing technologies and not least the product itself is required.

As a leading manufacturer in automation solutions, STIWA develops optimized production processes with the best possible overall effect. STIWA Processes and Technology (VT) contributes many years of know-how in automation-oriented product design and technology integration and therefore creates the best conditions for later high-performance automation.

As service provider we accompany our customers

from a product idea to a automation solution

New and further development

of products

Modern products often require new manufacturing processes in production. With a simultaneous development of products and their manufacturing processes, STIWA creates the optimal conditions for efficient and secure production of future mass products.

The parallel development of mechanics, software and electronics is a core competence of our development department.

Processes

Modern manufacturing processes require different processes. STIWA researches, develops and improves processes from their basic principles to their application in high-performance automation.

The correct and coordinated selection of necessary processes (laser welding, image processing, joining, gluing, etc.) results in high-quality and at the same time cost-effective products.

Manufacturing technologies

The use of adapted manufacturing processes and technologies is the basis for an efficient production.

Thanks to our long-time experience in production, you will make the leap from basic development to successful serial production.

Processes & Technology

ENGINEERING CUSTOMER PRODUCTS

- External/internal development incl. 3D component design and FEM calculation

- Software development, the core area of mechatronic products

- Product and process concepts along the value chain

- Technical design of prototypes and functional samples

- Guide for comprehensive development teams

PROCESS VALIDATION

- Process development on in-house process modules and test stations (presses, screws, US welding, joining)

- Practical result validation of new processes and technologies

- Production and start-up of functional samples and prototypes

- Attempts and validation of processes and functions for mechanical engineering

- Small-series production, parts management, coordination of product parts

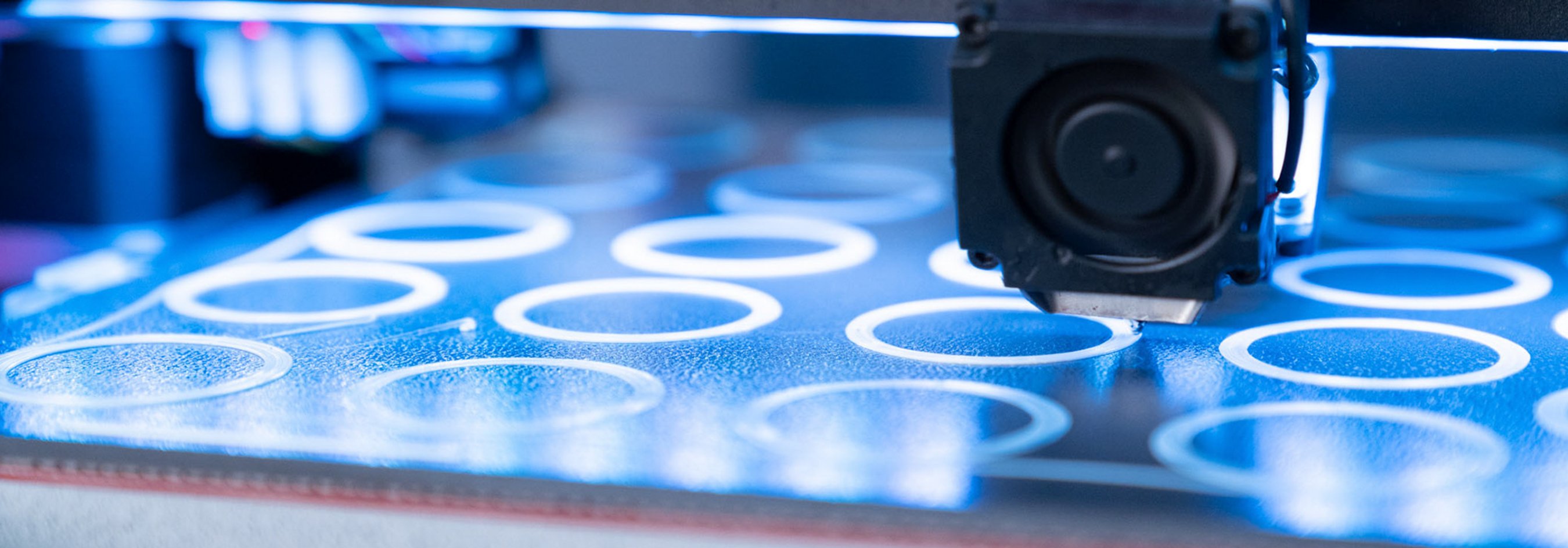

- Additive Manufacturing

TECHNOLOGY INTEGRATION

- Development of technical solutions for the manufacture of products in production lines

- Research, selection and purchasing of technologies

- Robot sequence and cycle time simulation

- Deadline monitoring, coordination and acceptance of technology acquisitions

- Support of suppliers and customers during visits in STIWA

- Writing PFH orders

- Procurement comparisons, test reports

- Laser competence center (welding, hardening etc.)

- Industrial image processing / vision systems (attempts, design, start-up,...)

MATERIALS ENGINEERING

- Advice and support for projects in materials engineering issues

- Handling of technical damage claims and customer complaints

- Advice, assistance, analysis and service in the areas of material selection, surface modification and coating, heat treatment of materials, tribology (friction and wear), corrosion and corrosion protection

Adjusted to the development of new customer products, we work every day on innovative processes for the successful high performance automation of tomorrow. With state-of-the-art technology and the corresponding operating equipment, processes are developed as well as their feasibility and functionality secured.

Markus Forstinger

Management Process & Technology