Increase OEE - 10 percent are always possible!

Defective feeding material that leads to increased rejects, incorrectly set screwing processes, that block the workpiece carrier for a long time and…

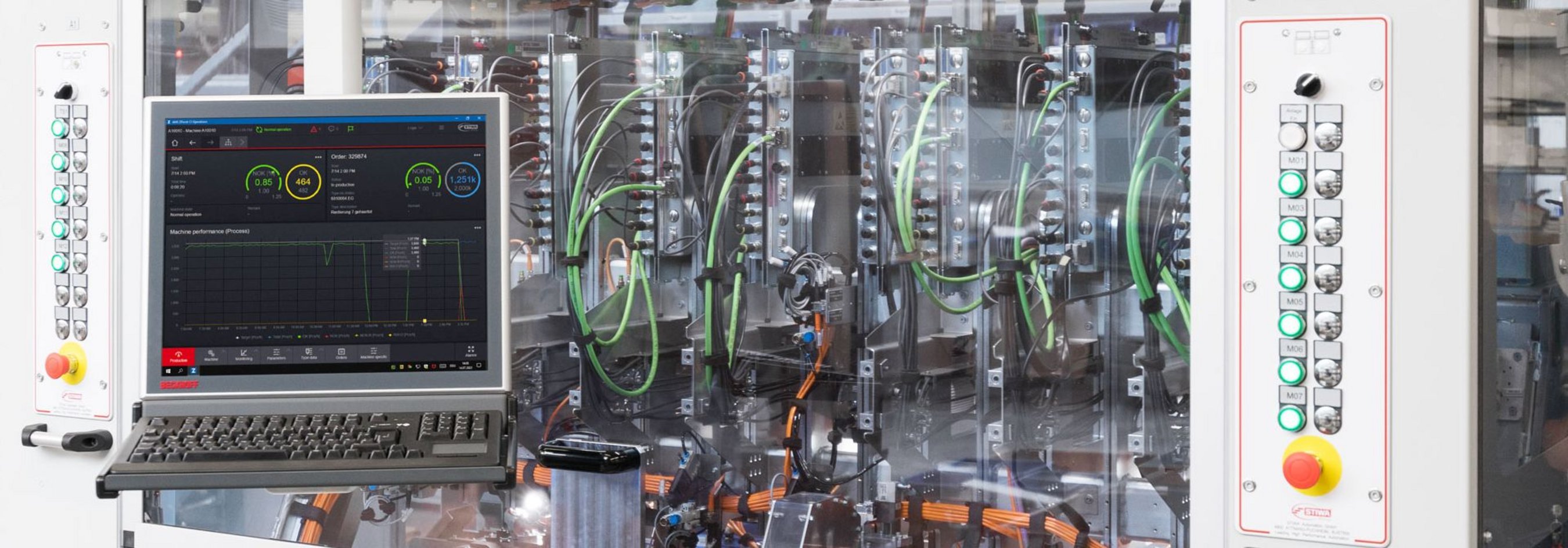

Universal line control for diverse machine parks and reliable processes

The STIWA control station software enables visualization and control of machines and systems independent of manufacturers or the control system behind them. Data driven decision making and data transparency at the production machine are our priority.

The modular and flexible control station – the cockpit for your machines and systems – offers solutions from order management to process control and type management. In doing so, we support functions such as a uniform and user-friendly user interface for reduced training and maintenance effort, SCADA functions, type changes without emptying the machines (flying setup), a virtual data pill for lossless management of parts and component data, and comprehensive recipe management with integrated type and release management.

Compatibility - Simple update

Central system AMS CI-Suite 1.25 compatible with local system 1.18

Recipe management

Central and continuous

Flying setup

Type change without running the machine empty

ORDER MANAGEMENT

→ Avoidance of operating errors thanks to an intelligent order management system

ALARM MANAGEMENT

→ Faster troubleshooting

RECIPE

→ Standardized management of type properties

Administration & documentation

→ Standardization across machines and manufacturers

REWORK STATION

→ Reduction of rejects

VIRTUAL DATA PILL

→ Safer processes and shorter cycle times

Defective feeding material that leads to increased rejects, incorrectly set screwing processes, that block the workpiece carrier for a long time and…

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/7/csm_Produktfoto_LTM-CI_Kompaktautomation_3000x2000_PS_2019-01-25_S1A00814_2b18ea0c79.jpg)

Continuous development of the software, uniform software standards and the same user interface - with STIWA Manufacturing Software maintenance various…

To optimize their production processes and increase machine efficiency significantly, Festo AG capitalizes on Manufacturing Software from STIWA.

Dipl.-Ing. Michael Meisel

Head of Division Sales and Product Management STIWA Software