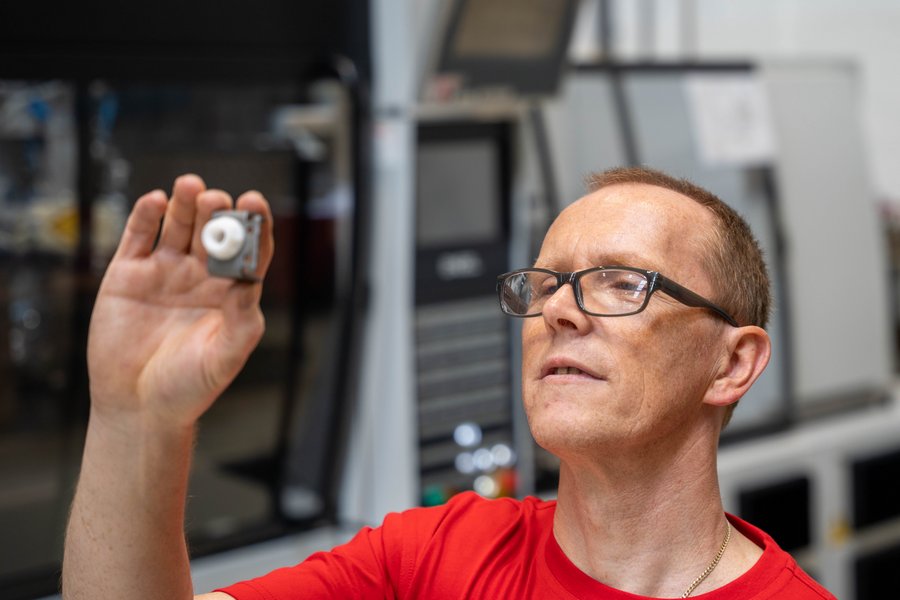

High-grade individual components & assembly groups

of plastics or metal-plastic composites

Ready for cost-efficient and effective manufacturing at the highest level?

STIWA Advanced Products stands for premium plastic products from Austria and Germany - ensuring shortest lead times and cost-efficient production.

Due to decades of experience in the production of high-grade individual components and assembly groups of plastics or metal-plastic composites, we are a strong partner for customers from a variety of industries all over the world.

different

components in production

parts per month

Years of injection molding

experience

Customized production from one source

Due to our vertical integration and closed feedback loops from prototype development and toolmaking through to large-scale production, we are the ideal partner for any and all plastic products meeting highest requirements in terms of precision and performance.

No matter if your product is left to be developed or can already be manufactured, our specialists will see you through each phase of your plastics project - from engineering to cost-efficient and high-grade serial production.

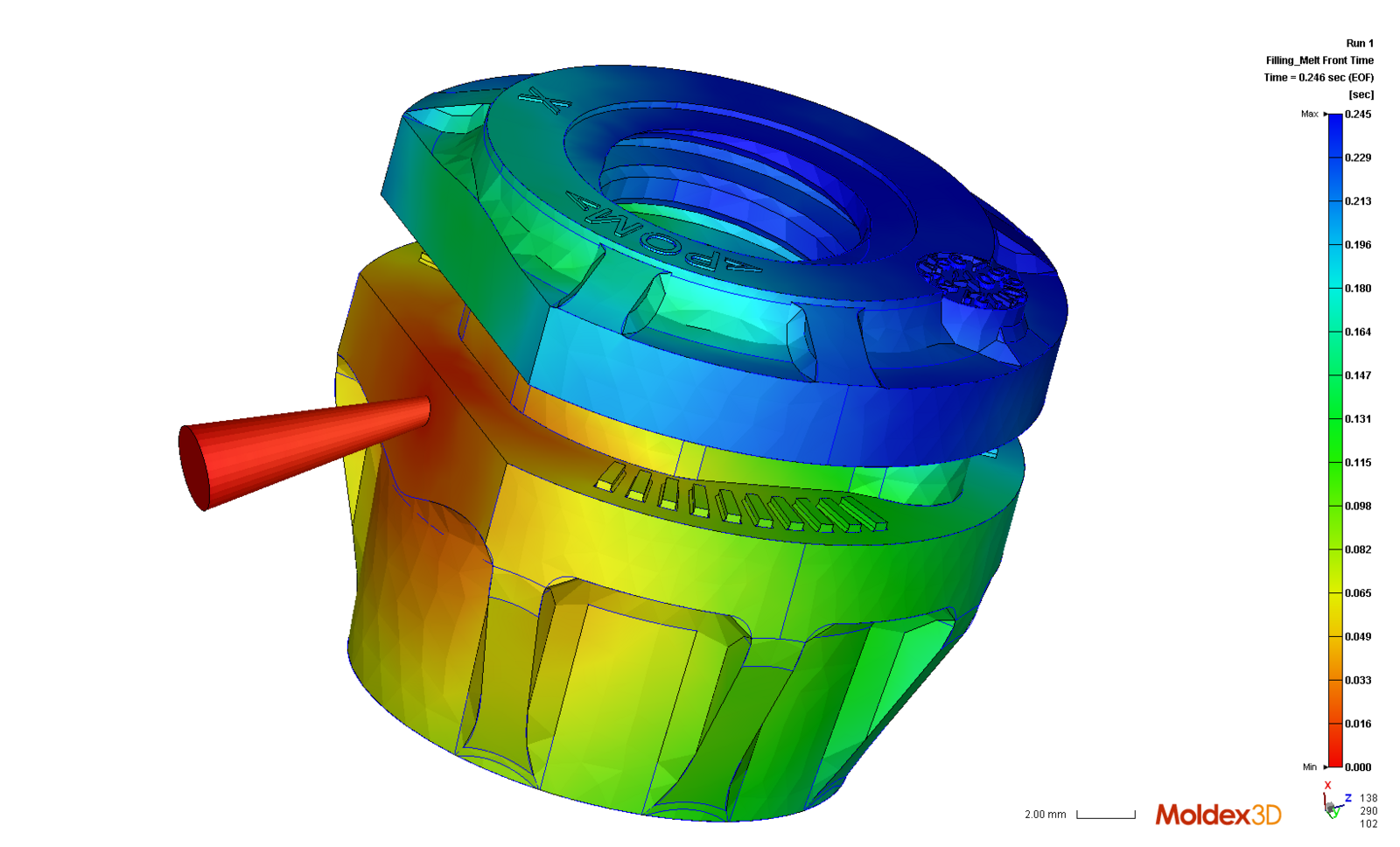

Development

From design and simulation through to component testing:

being a one-stop shop in plastics manufacturing, STIWA Advanced Products offers customized component developments meeting highest standards, both for individual components and assembly groups of plastics and for assembly groups of metal-plastic composites.

Moreover, 2-component injection molding of demanding multi-function parts as well as metal extrusion coating are among our core competences. The portfolio is completed by further processing technologies (assembling, ultrasonic joining, etc.) mastered with decades of experience.

This is your benefit

HIGHLY EXPERIENCED & COMPREHENSIVE DEVELOPMENT TEAM

from the departments Mechanical Design, Simulation, and Project Handling

REGULAR FEEDBACK LOOPS

from serial production due to joint development and production from one source

MANY YEARS OF EXPERIENCE

in the fields:

» Medical engineering

» Automotive

» Electronics

» Technical Products

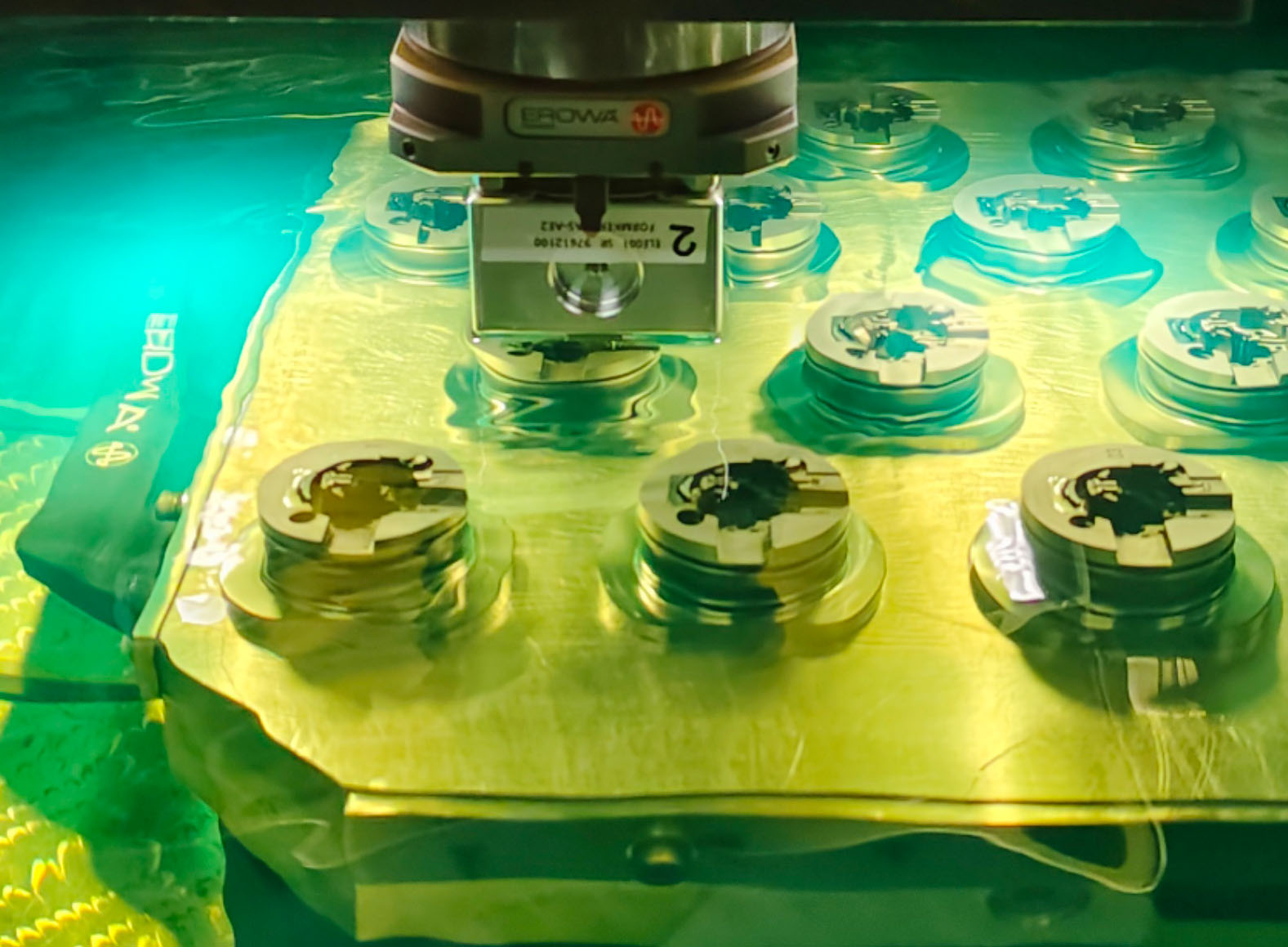

Toolmaking

Whether it be components for the automotive industry, medical engineering, technical application, and many other fields:

with their comprehensive expertise in the manufacture of micro to macro components, from prototypes to series tools, 2-component tools, as well as own in-house tool testing, STIWA Advanced Products stands for precision toolmaking and plastic products of highest quality.

Of course, we will advise you already in the design phase of your components with regards of a plastic-compatible component design and will submit a free quote right away.

This is your benefit

MORE THAN 2 BILLION COMPONENTS

produced by means of STIWA tools

TOOL GUARANTEE

for up to one million cycles

PRODUCTION

on 67 manufacturing machines

3D DESIGN

using SolidWorks

MANUFACTURE

to a precision of 5µm

MOLD UNITS

up to 800 x 500 mm

AIR-CONDITIONED MANUFACTURE

CAM SYSTEM FIREMILL

Injection-Molding

Manufacture of prototypes or production on demand:

ultra-modern automated STIWA injection molding production machines are available for each and every production requirement delivering precision products from simple to complex extrusion-coated injection-molded components as well as 2C injection-molded components.

Due to state-of-the-art material feeding, automated production, as well as in-process functional quality control, we guarantee short processing times and favorable manufacturing costs.

This is your benefit

133 DIFFERENT COMPONENTS

in production

MORE THAN 30 YEARS OF EXPERIENCE

in injection-molding

MORE THAN 55 MILLION

parts per month

COMPONENT VOLUME

2.5 bis 400 cm³ shot volume

SPIRAL DIAMETER

(8)18 to 55 mm

CLOSING FORCE

500 kN to 2,000 kN

MAXIMUM TOOL SIZE

700 x 560mm

MAXIMUM TOOL TEMPERATURE

140 degrees Celsius

Component Testing

Due to their comprehensive, well-established, and long-standing partner network, the in-house development of functional testing scenarios, as well as the creation of suitable testing devices, STIWA Advanced Products offers comprehensive component testing and a broad portfolio of plastic-relevant component tests (alternating climate test, media resistance).

This is your benefit

> 2,500

tests per month

> 20 MILLION

load changes per month

> 980

test devices

IMPACT TEST

LIFE TESTS

MECHANICAL STRENGTH

(tensile strength, deflection, etc.)

Karl Bergthaler

Head of plastics center