Systems & Components -

The right automation for your production

As a leading manufacturer in automation technology, our products, projects and services have enabled optimized technology integration with the best possible overall effect for many years.

Through the focused interplay of mechanics, software and electronics we achieve product solutions that guarantee the greatest possible flexibility, standardization and safety.

We accompany our customers along their entire value chain and are a professional partner for special mechatronic solutions!

System technology

Fast transport systems, handling components, feeding technology and complete systems as well as flexible software solutions and continuous analysis options are the basis for efficient production.

STIWA Group offers the right systems for this when high cycle times are required and complex tasks have to be integrated.

Loosely and rigidly linked system solutions are available for parts transport, from the smallest components to high loads of more than 200kg component weight.

The modular design of the assembly systems offers a continuous automation system from high-performance production to flexible assembly cells.

Complete systems

STIWA miniature automation systems represent the most modern and complete assembly systems in the subsecond range for small series of up to 30 mm body diagonal.

- Smallest space requirement

- Short cycle times

- Technology integration

- Best ergonomic and user friendly operation

Machine protection

In machine protection, STIWA combines 50 years of experience in mechanical engineering with comprehensive know-how

- Safe & functional

- Modular system

- different sizes

- Self-supporting

Transportation systems

Loadable - Fast - Flexible

With STIWA transfer systems, we offer you the highest performance in terms of speed and positioning accuracy.

By means of a rigidly or loosely linked conveyor system, STIWA transfer systems are trimmed for high performance and impress with minimal workpiece carrier change time. We guarantee the highest possible service life and reliability.

Feeding systems

Adaptive – Modular – Intelligent

High performance control cycles enable the control of your processes in almost real time. The networking is carried out by means of included basic software and the convenient integration ensures rapid implementation and optimized control.

A possible ERP connection for operating and product data acquisition opens up further analysis possibilities and document important parameters of your production.

- Highest flexibility: Simple adaptation due to modular device design

- Combinability: Stand-alone solution with direct operation on the device enables connection to third-party systems as well.

- Expandability: A wide range of feeding parts is possible (complex part geometries).

- Shortest possible set-up times: Quick exchange devices for straightening conveying tracks

- Automatic hopper emptying as well as hopper filling level monitoring

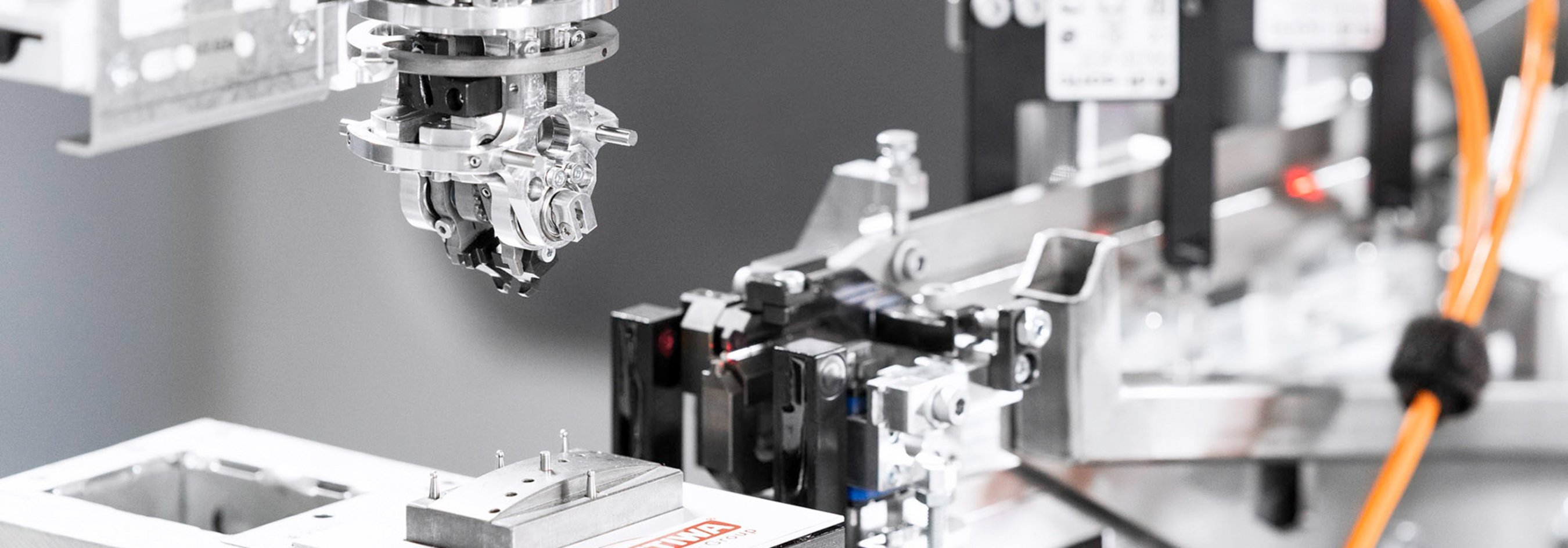

Handling systems

robust – durable – precise

STIWA axes and grippers are specifically designed for the requirements of high-performance automation.

In the area of handling components STIWA sets its own standards in the areas of quality, precision and durability and offers highly functional components with corresponding assembly interfaces.

Intelligent - Dynamic - Gentle

Modular – Self-supporting – Functional

Robust – Durable – Precise

Quick – Precise – Smart

Flexible – Variable – Compact

Functional – Flexible – Universal

Reliable – Intelligent – Versatile

Robust – Durable – Precise

Precise – Versatile – Gentle

LTS-CI, LTH-CI, LTL-CI

Adaptive – Versatile – Intelligent

From development to stable production: By focused interplay of mechanics, software and electronics we achieve product solutions that guarantee the greatest possible flexibility, standardization and safety and deliver optimized software integrations, components and accessories as the ideal addition for mechanical engineering!

Markus Hauer

Head of Business Unit Mechatronic Systems