Comprehensive automation expertise:

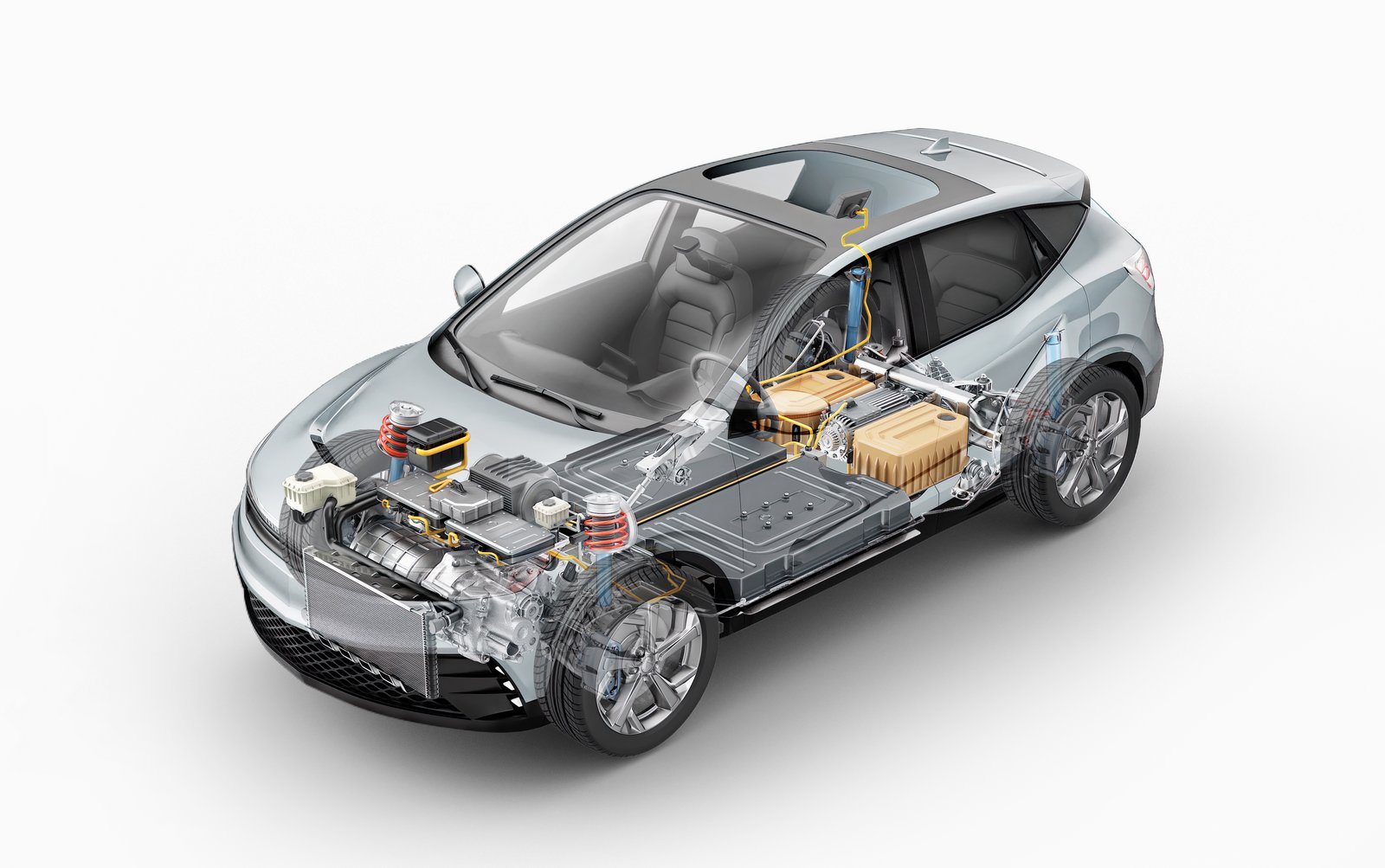

Complete solutions for New Mobility

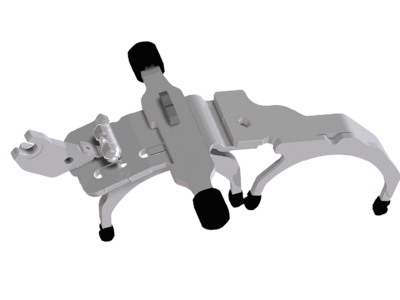

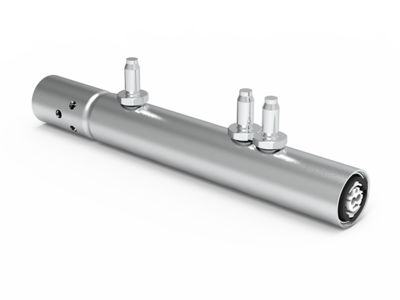

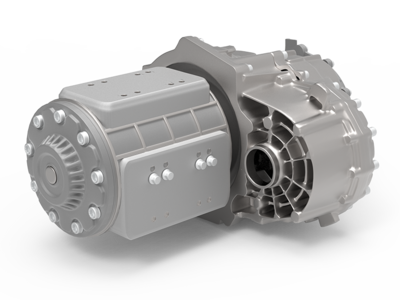

With decades of experience as a provider of automation solutions and a Tier 1 supplier of automotive components, STIWA is a leading player in the industry. Our wide range of services includes the development of customized solutions, from high performance assembly machines to flexible, modular and highly complex systems. At STIWA there is no limit to the size of a project - we deliver both small and large mechanical engineering projects. Discover the possibilities of STIWA as a reliable partner for your automation needs.