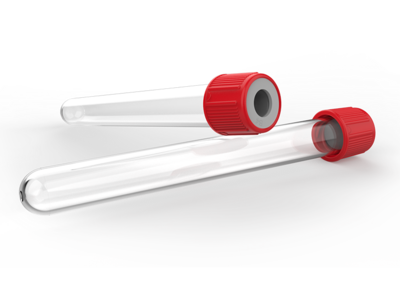

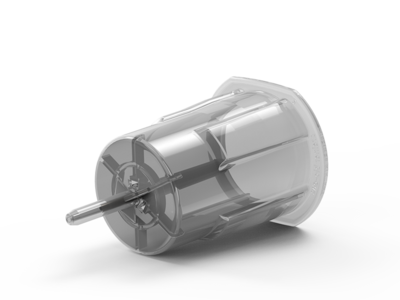

Comprehensive automation expertise:

Complete solutions for Life Science

STIWA is the experienced partner for automation solutions in the healthcare sector. From high-performance assembly machines to flexible, modular systems, and fully linked or standalone stations, our solutions cover both cleanroom and controlled environments. Our holistic concepts take into account environmental factors, reusability, total cost of ownership, and product design optimized for automation. With decades of expertise in medical product manufacturing, we continually enhance the efficiency and precision in the production of medical and healthcare products.