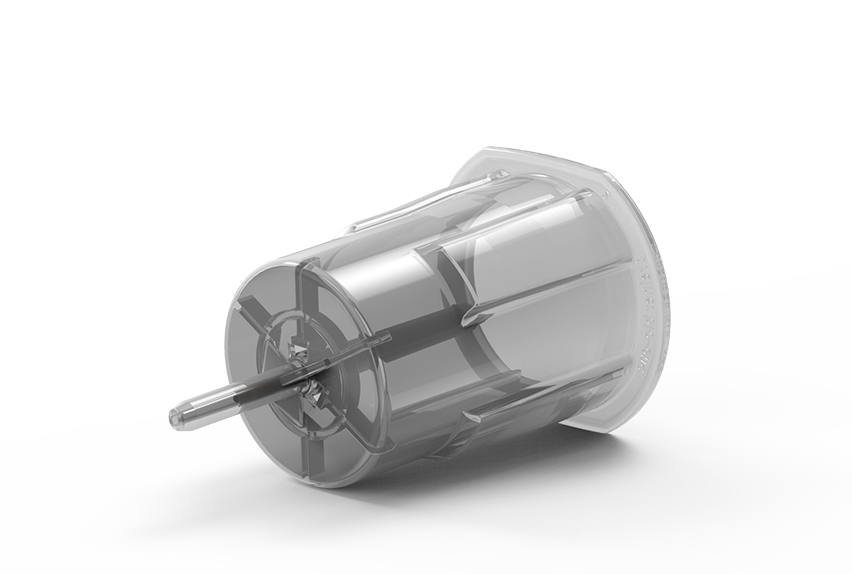

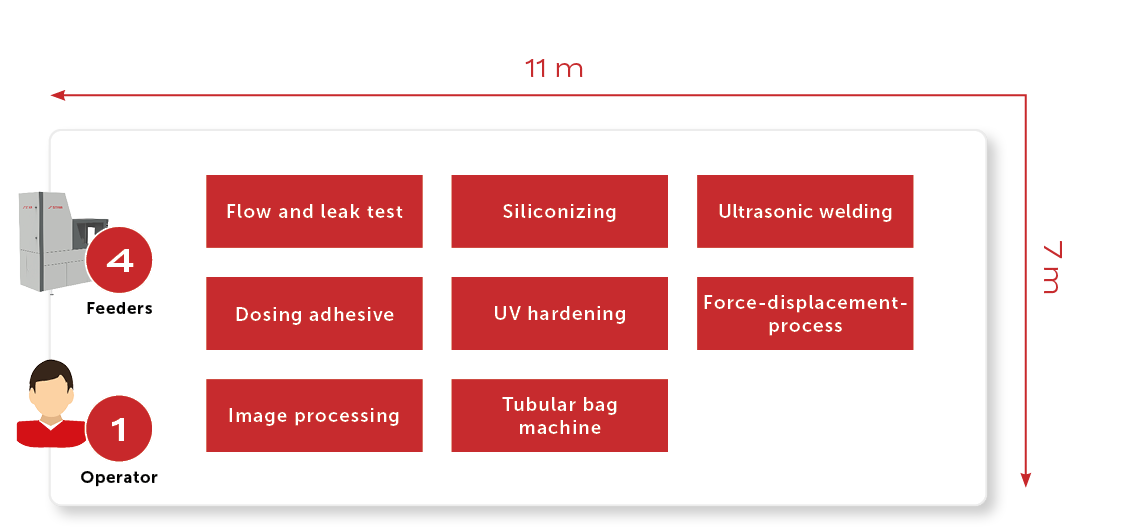

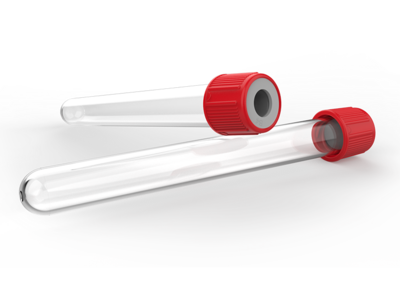

In this fully automated STIWA machine, tube holders for blood sampling are assembled, checked and packaged. The tube holders act as adapters between the canula and the sample tube, making handling easier for medical personnel and minimizing the risk of injury from contaminated needle tips.

The individual components are fed in, then the needle is glued into the needle holder. After testing the correct gluing and performing a flow test, the rubber protection is mounted over the needle tip. The assembly group is transferred to the outer sleeve and both parts are ultrasonically welded. After testing the fit, the tube holders are individually packed into bags and delivered either in cartons, boxes or in palletized boxes.