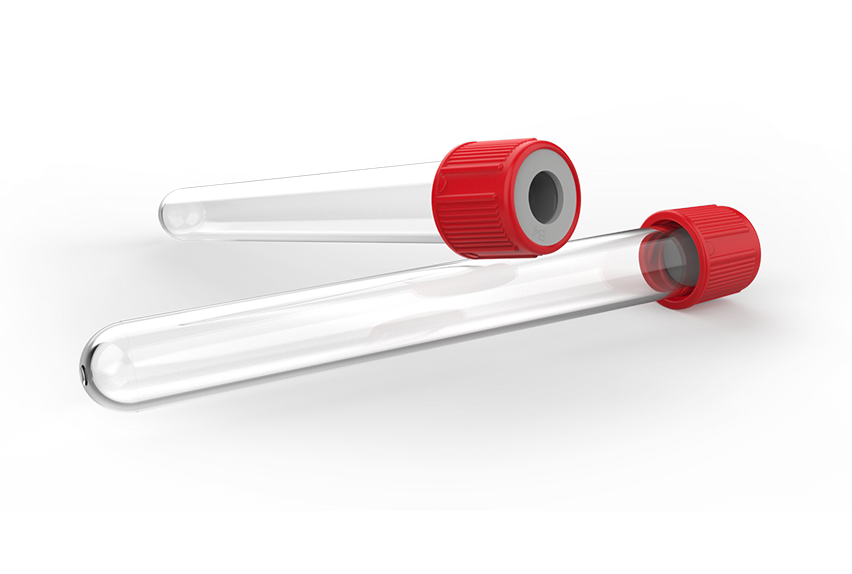

In this fully automated STIWA machine, blood collection tubes are assembled, which are used in medical treatments and in the laboratory.

The tubes and stopper components are inserted via two feeders and checked for integrity. The tubes are sprayed with a proprietary fluid required for laboratory testing, then it is dried. Then, the tubes are labeled. The finished products are sorted into trays in batches of 50, wrapped in a film and sealed, then packed into a finished carton and placed on a pallet.

LABELING IN CONTINUOUS OPERATION

An ingenious process allows the correct application of the labels in continuous operation. The tubes are removed from a previous station and placed seamlessly next to each other in the correct position. The speed of the conveyor chain and the station must be synchronized to ensure the application of the labels (continuous motion removal from the liner and placement).