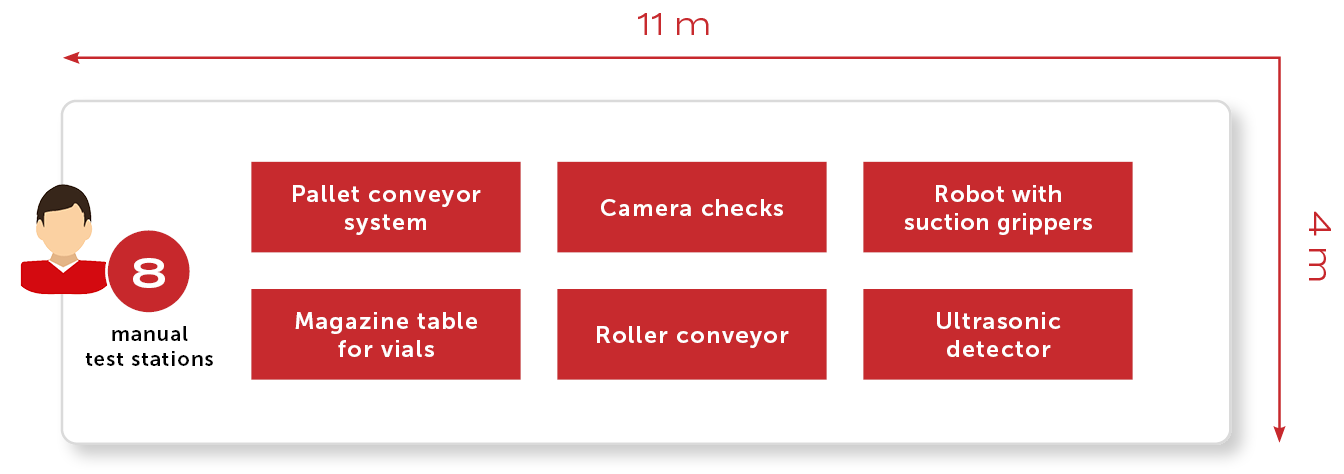

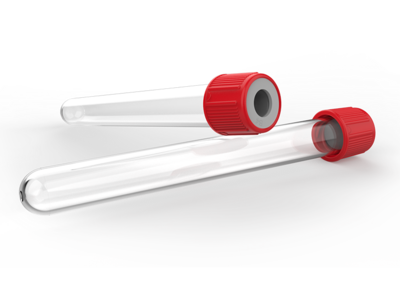

This line from STIWA is designed to transport vials to and from an automated visual inspection machine (AVI). Careful and precise handling of vials is crucial to minimize the risk of glass breakage.

The vials are placed in trays on pallets, are picked up by a robot with suction grippers and transferred over to a staging table, from which they are automatically fed into a conveying system. After inspection, the vials are transferred from the conveyor belt and reloaded into the trays. If the test results are negative, they are automatically sent to manual workstations and checked individually there.