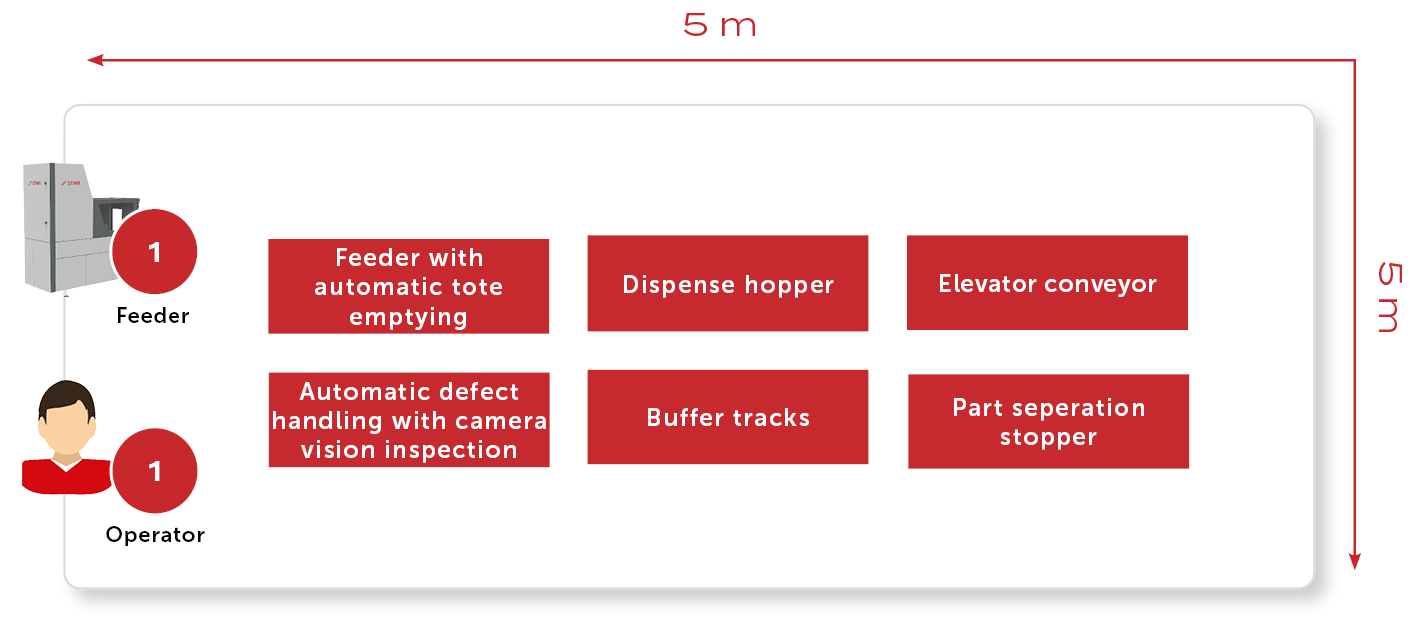

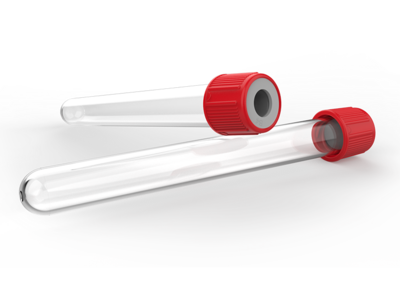

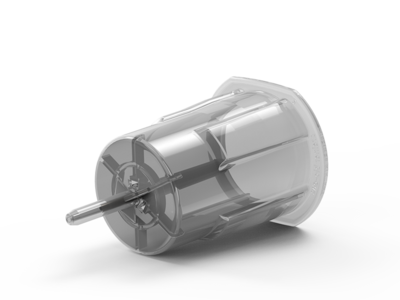

This STIWA system is designed to precisely feed medical fluid spike and transport them into a packaging system in the correct orientation using a handling and loading system. The system ensures the efficient supply of product parts for the subsequent packaging process.

The fluid spikes are delivered by a AGV transport system with ERP connection and automatically transported to the hopper of the feeder via a crate emptying handling system. They are then manipulated and aligned in five separate feeding lanes by means of high-level conveyance. An anti-jamming unit checks each part by camera. After buffering, the parts are separated by stop units. The feeding handling system picks up 25 parts and inserts them into the packaging system simultaneously.

COMPREHENSIVE QUALITY CONTROL FOR PRODUCT INTEGRITY

A continuous camera vision inspection of the parts is carried out in a continuous process, whereby products with deviations or foreign objects are immediately sorted out. This is crucial to ensure that no incorrect types enter the down stream processes.