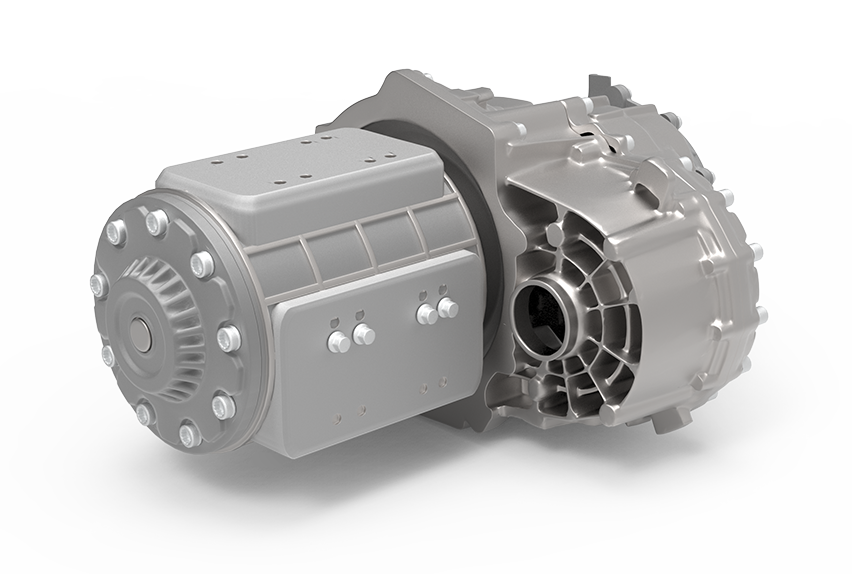

This machine produces drive motors for hybrid and electric vehicles. The engine systems are installed in cars and commercial vehicles.

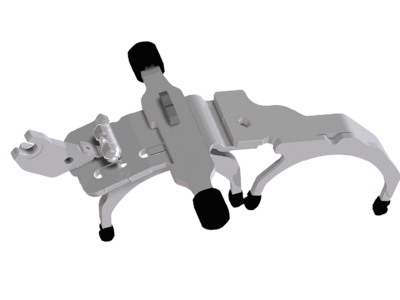

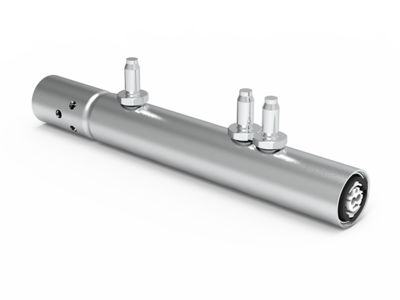

Rotors, stators and other components are introduced into the machine and separated using an automatic transport system. Joining and screwing processes are implemented partially or fully automated. Integrated electrode pre-assembly, electrical tests and leak tests ensure the highest quality. Two machines from third-party manufacturers are seamlessly integrated and coordinated by a higher-level control system. The transfer for final inspection and packaging is automated.

NEW MOBILITY

250,000 electrical drives

per year – made in Europe

E-MOTOR