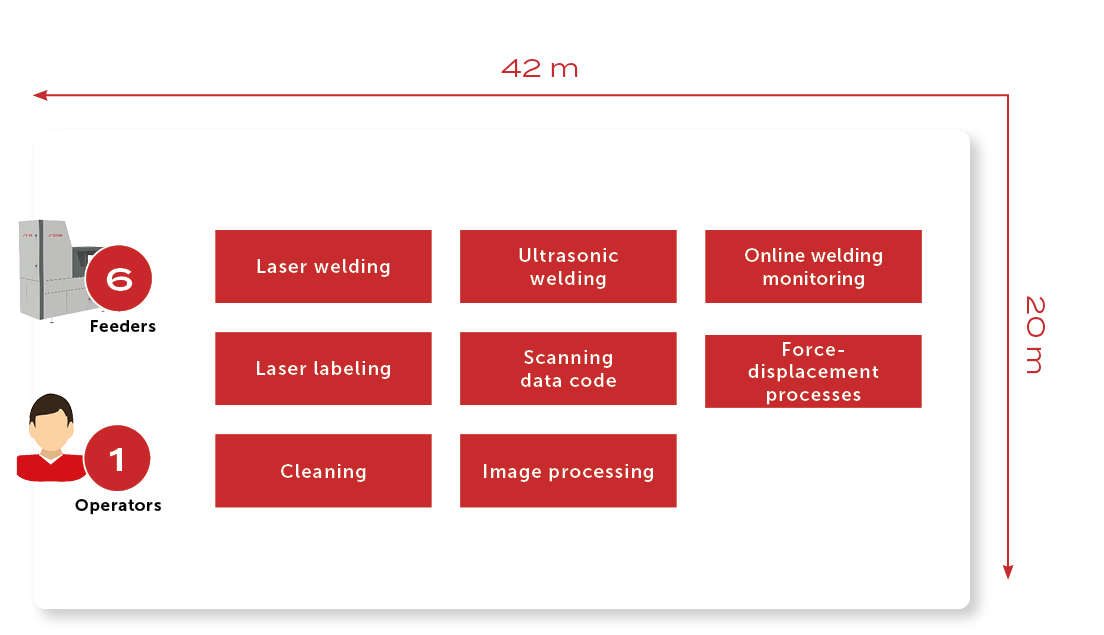

Covering an area of 850 m², this system combines a complete production cycle from the feeding of individual parts to the output of tested and cleaned assemblies.

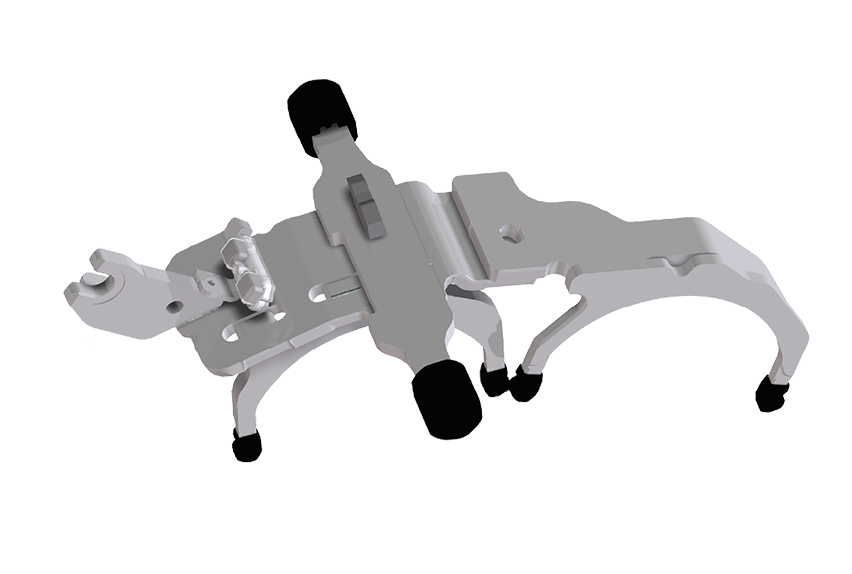

The individual parts of the shift fork are automatically fed before welding and transported to welding stations. A cleaning system completes this network. Every year, several million shift forks for automatic transmissions are manufactured on high-performance automated laser welding systems at STIWA's Gampern site.