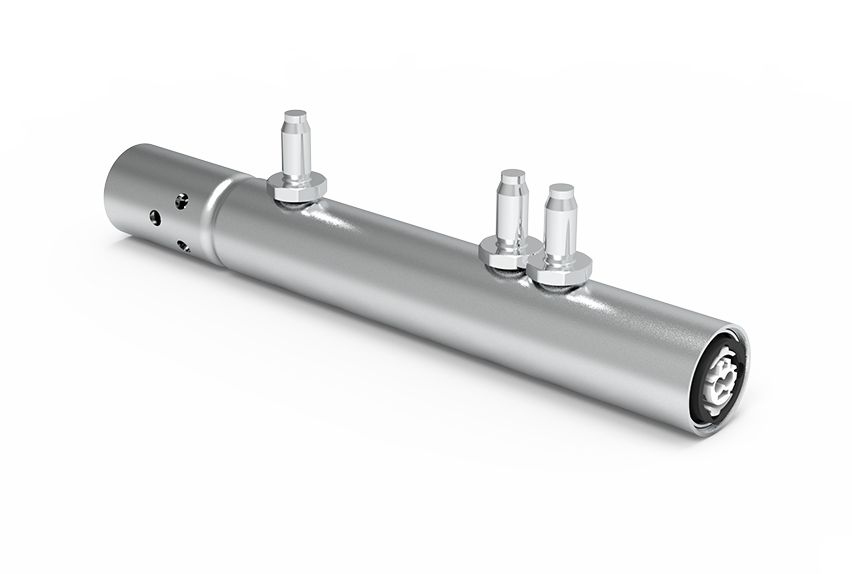

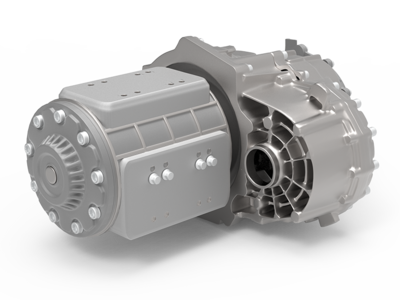

In this fully automatic STIWA machine, ignition modules for side airbags are assembled, tested and packaged. These are used in gas generators in cars and are a kind of „mini-rocket“ that triggers the airbag in an emergency.

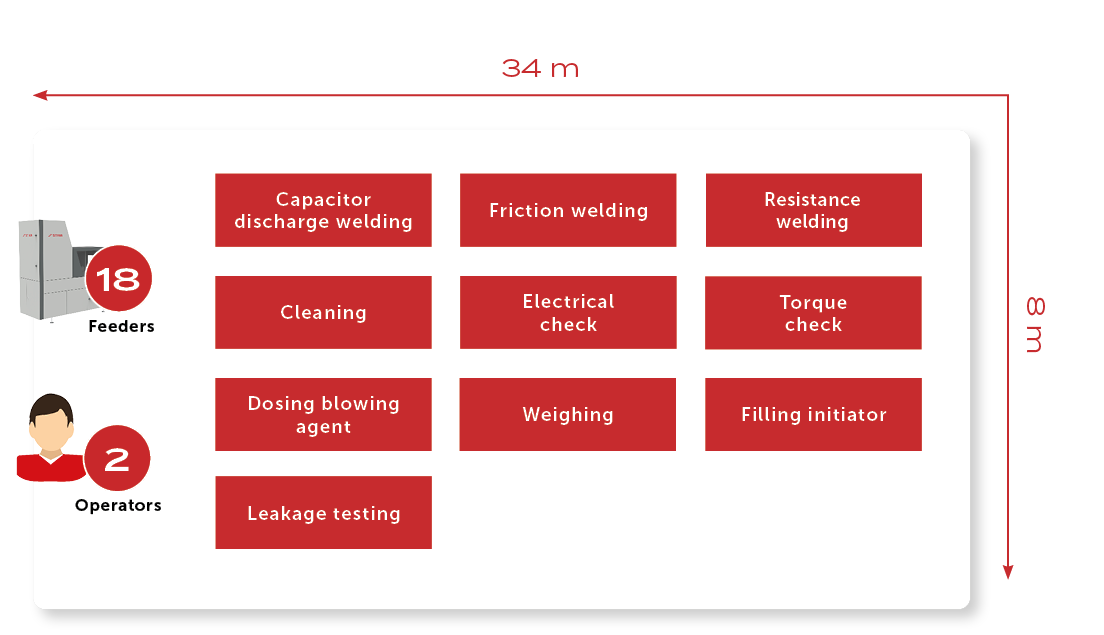

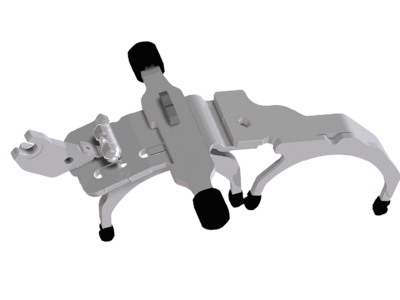

The individual parts are fed as bulk material, isolated and processed in welding and joining processes. The propellants are placed in buckets in the explosion protection devices and emptied into the protective enclosures, dosed and filled into the assembly. Functional tests are then carried out and the assembled parts are labeled. The finished products are prepared fully or partially automatically in disposable or reusable packaging for transport.

NEW MOBILITY

First product samples

within 20 weeks

GAS GENERATOR FOR AIRBAGS