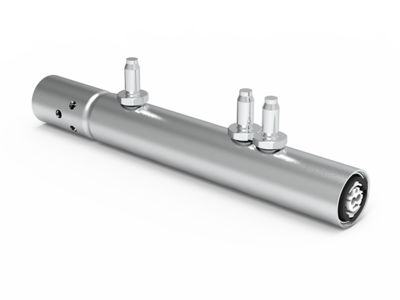

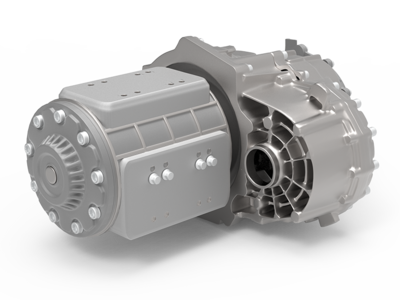

In these two STIWA machines, components for cell contacting systems are manufactured. These systems are installed in electric vehicle (EV) batteries and form the battery‘s electrical network.

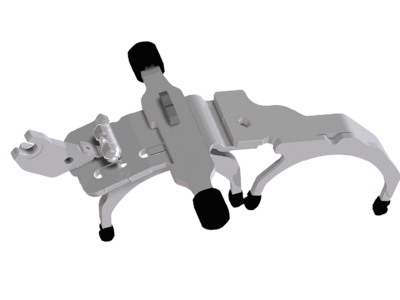

With a size of 800 m², two adjacent machines handle the production: the first machine welds the lower part of the cell contacting system onto cylindrical cells, while the second machine welds the upper part. The two independently manufactured components are then assembled and subsequently installed in vehicles. The components are loaded manually using lifting aids and conveyor belts

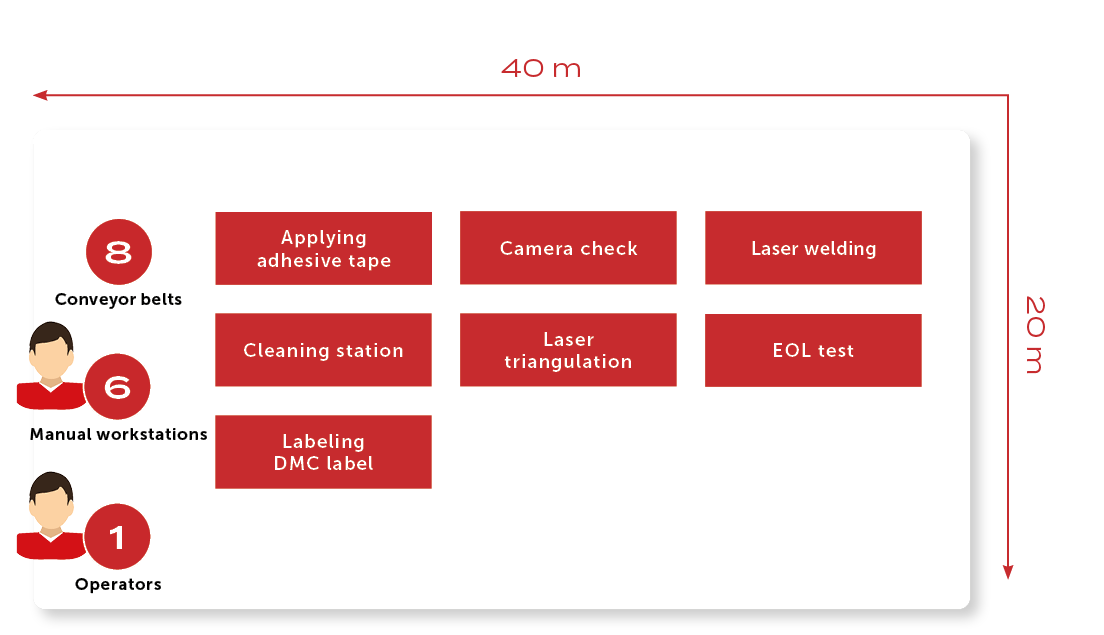

TEN PROCESSING POSITIONS IN 40 SECONDS

The robot works precisely and quickly, moving to up to ten different processing positions in 40 seconds. Well-designed process steps enable a short overall machine cycle time. During the welding process, 32 welding seams are created on each part within 35 seconds.