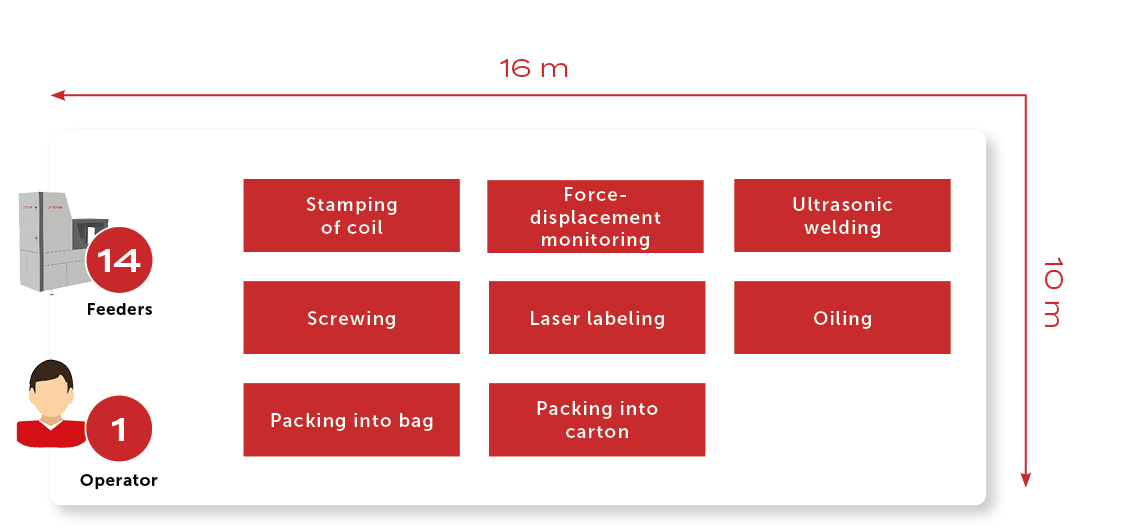

In this multi-part STIWA production system, power and audio plugs are assembled and packaged. These are used in music productions, at events and in broadcasting.

The machine group consists of 3 assembly lines, which put together various products such as plug insert, housing and clamping, sleeve packaging, and then placement in bags or as bulk material in a cardboard box. The individual components are introduced via 14 feeders – including some special devices and a decoiler.