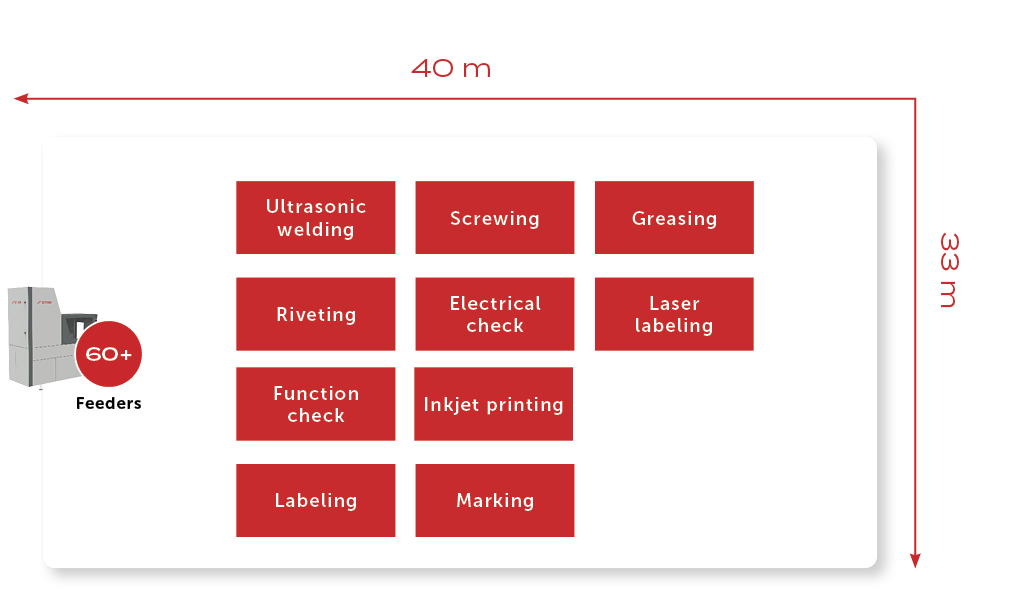

In this multi-product STIWA production line, sockets and light switches are assembled, tested, labeled and then packed into

cartons.

The output is less than one second per finished part. The products are manufactured in various production steps. The parts are automatically packed in 10-pack cartons. Pre-assembled products are placed on a separate output belt for manual processes and completion.

Gira relies on ‘Made in Germany’. With cycle times of up to 120 tested and packaged parts in 2 minutes with tested quality, we ensure our international competitiveness at the German manufacturing site.

Christian Feltgen

Technology Director Gira