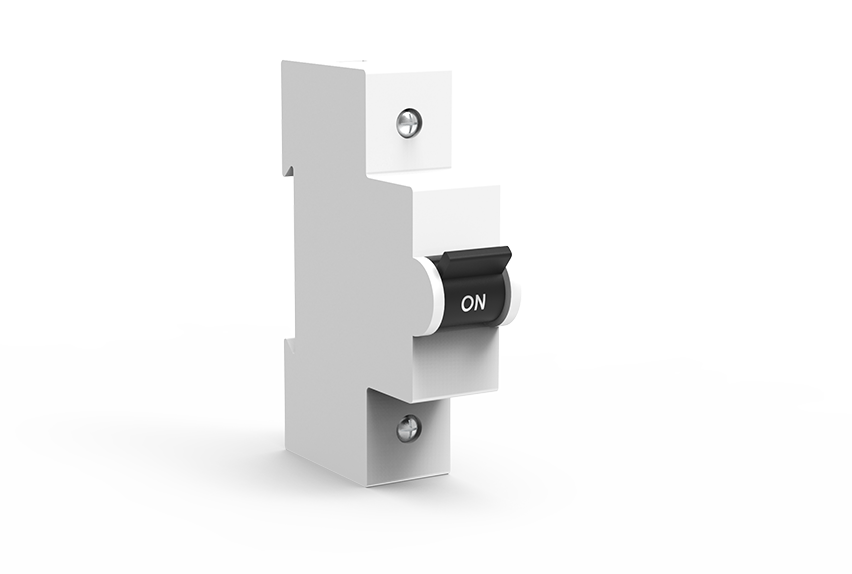

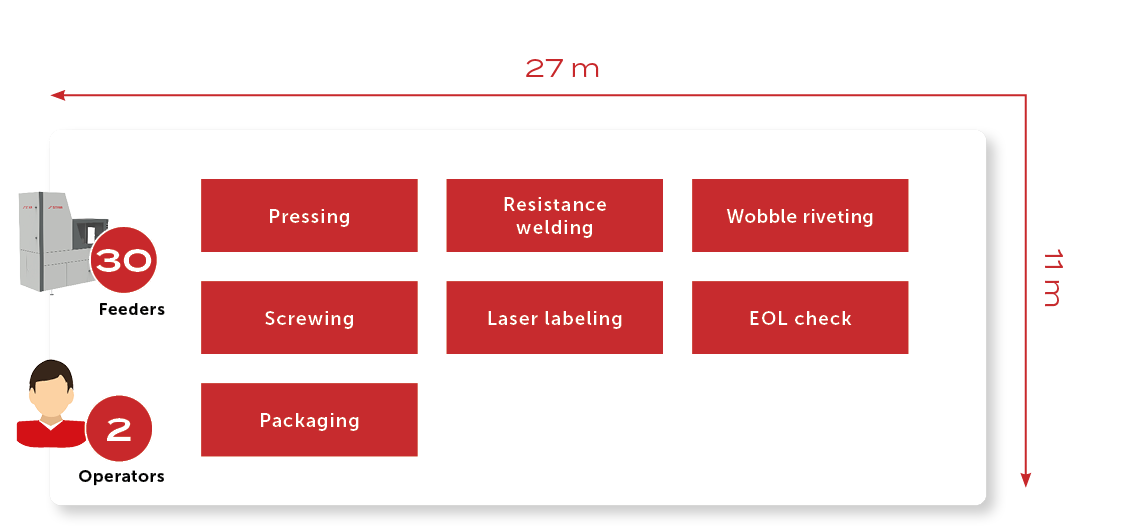

This fully automatic STIWA machine produces single-phase circuit breakers. These protect electrical systems in fuse boxes from overload by automatically interrupting the circuit in the event of a fault.

The miniature circuit breaker consists of 33 individual parts, which are supplied and assembled step by step. This assembly line handles a wide range of product variants. Finished parts are placed on an output belt or conveyor belt at the end of the assembly process. The system is connected to an intralogistics system.