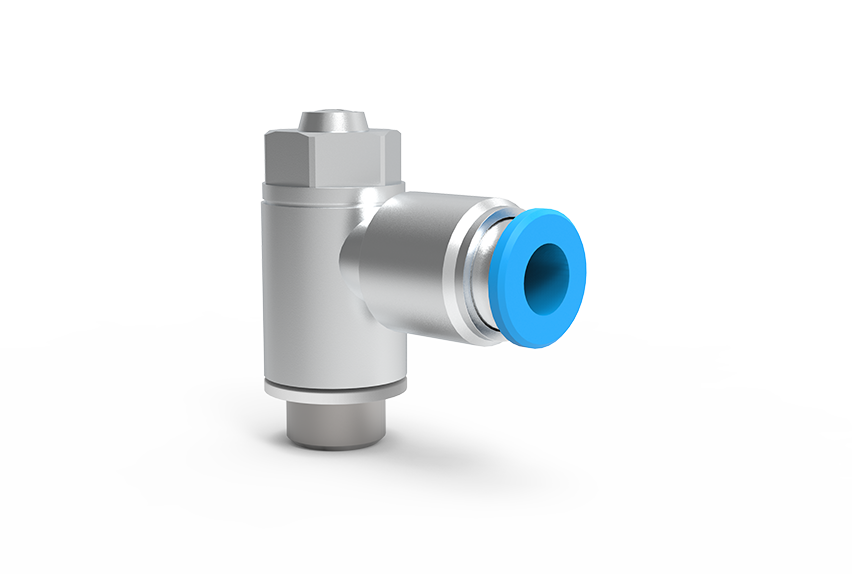

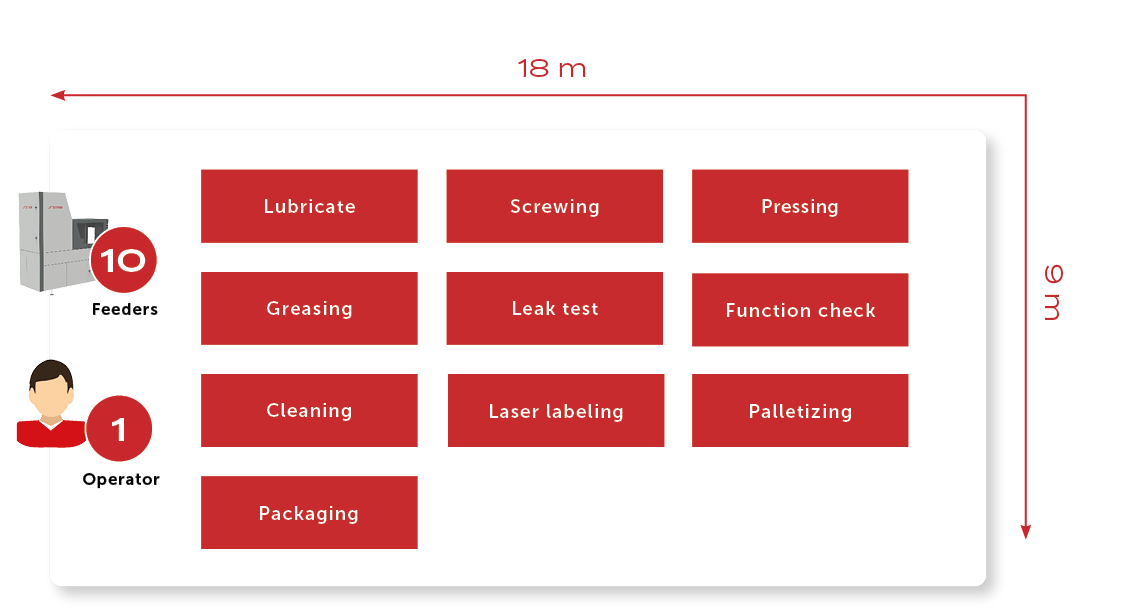

This STIWA machine assembles, tests, labels and packages throttle check valves. These are used, for example, in hydraulic systems of machine tools.

The components are fed fully automatically into the machine using flexible feeding devices, detected by a camera system, gripped with handling and transferred to an assembly unit. The components are joined, glued, screwed, greased, laser-marked and tested for tightness. Finally, the valves are individually packed in tubular bags and dispensed in boxes.