Our proven process for your success

The STIWA project management process ensures that your project is implemented on time and within budget. With our proven project structure, we work in partnership with you to reliably achieve schedules, milestones, and goals.

Contact your automation expert now

Step 1

Demand analysis

Understanding your situation. Set goals. Plan your budget.

- Analysis of your current production processes

- Identification of the best automation options

- Support with process development and design (in advance if required)

- Construction of prototypes and testing of sample products

- Support with automation-oriented product development

- Development of initial rough concepts

- Calculation of ROI and presentation of financing options

- Development of a roadmap for step-by-step implementation

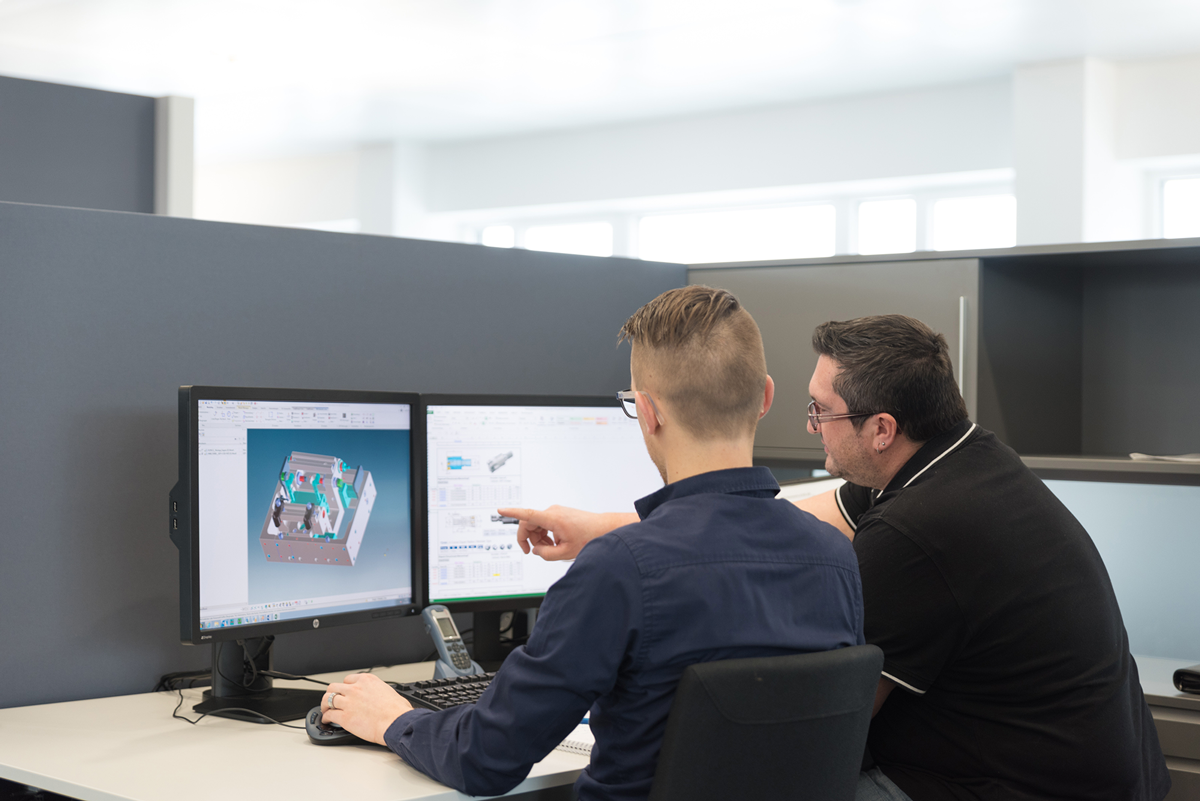

Step 2

Concept development

Development of technical solution. Perform tests.

- Detailed definition of requirements

- Design of future-proof solutions

- Proof of concept for critical processes to validate the concept

- Simulation of production processes using digital twins, comprehensive if required

- Integration into your existing system

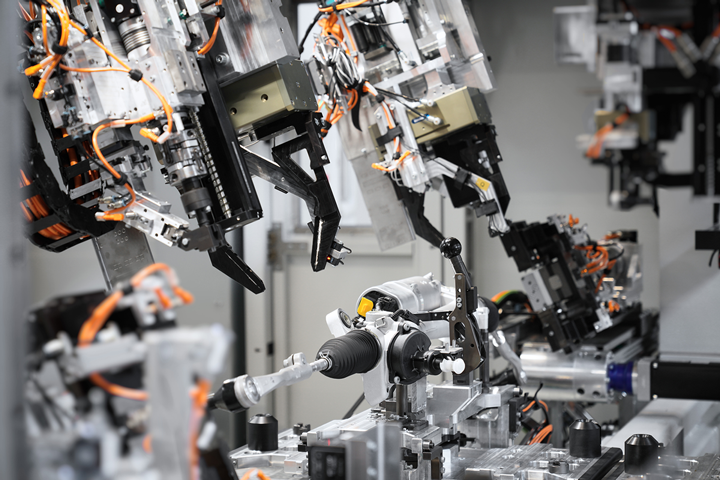

Step 4

Installation and start-up

Install the machine. Testing. Acceptance.

- Systematic implementation

- Testing of all functions

- Data collection already at station level

- Collection and continuous evaluation of all relevant data for optimal start-up

- Factory Acceptance Test (FAT) / Pre-acceptance at the STIWA plant

- Preparation for on-site installation

Step 5

Installation and start

Installation at your site. Training the team. Start successfully.

- Installation and start-up on site

- Ensuring process quality and machine performance for a smooth production start

- Site Acceptance Test (SAT) – final acceptance at your site

- Training opportunities in all relevant areas – from operators to production managers

- Handover to your operations team

Step 6

Monitoring and optimization

Measure performance. Optimize processes. Increase success.

- Live dashboard monitoring of all key performance indicators

- Warning systems in case of problems

- Continuous performance improvement

- Digital knowledge management

- Regular performance reviews

- Optimization of process performance (availability, cycle time) and quality

The STIWA advantage

- Reliably meet time and cost schedules thanks to proven project structure

- Personal support by technical experienced project experts

- Reduction of time effort, errors and costs due to standardization and proven reference solutions

- Methodological process with ISO certification

- Long-term partnership for sustainable success

- Continuous innovation due to systematic improvement

- Optimization with award-winning STIWA shop floor software