Highest quality standards

at reduced weight and costs

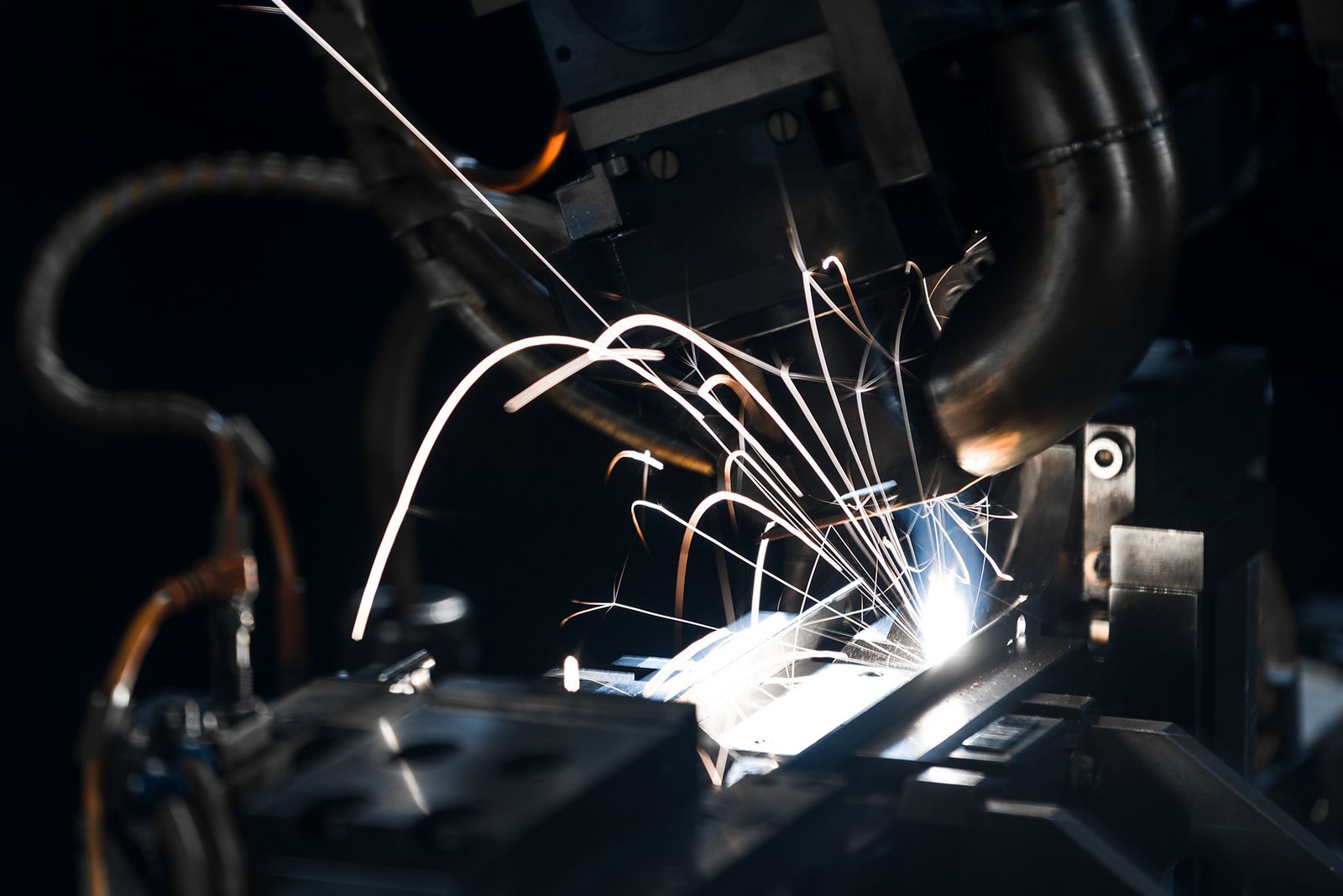

Technological leadership in comprehensive laser applications (welding and hardening) and comprehensive series experience in laser welding for more than 20 years enable STIWA Advanced Products to produce high-grade products meeting top-quality standards.

STIWA creates more than 1 million welding seams every day!

Customized product design

Already in the phase of jointly analyzing existing or future products, we develop - together with our customers - all those product solutions that can be implemented with a view to easy automation and laser welding.

In doing so, we pursue the several goals: highest efficiency, best quality due to an improved meeting of requirements, and cost saving due to significant weight reduction of the laser-welded product.

Have Your Product Developed for Laser Welding and Automation

STIWA laser welding processes allow highest welding speeds - many times higher than those used in conventional welding processes.

Due to the low heat input, results with minimum distortion can be realized. Thus, the manufacture of tightest tolerances is possible without rework.

STIWA series experience in laser welding for more than 20 years, in

- Large-scale production (highly automated laser welding)

- Small-scale series (manual clamping, automated laser welding)

From the prototype to large-scale production -

everything from one source

We’ll be glad to provide our experience and support you in switching from conventional welding processes to the next technological step of joining technology.

Benefit from shortest development and implementation times due to the high degree of vertical integration realized by STIWA:

- Laser-welding-oriented design

- Simulation and calculation

- Prototype construction

- Testing

- Fixture construction and mechanical engineering

- Toolmaking

- Parts manufacturing

The STIWA laser welding portfolio starts with very thin sheet of 0.1 mm. It is no longer necessary to invest in thicker plates needed for conventional welding processes.

In case of high mechanical requirements, we use our high-performance lasers to join components of up to 9 mm steel!

The following materials can be welded:

- Deep-drawing steels, fine-grained steels up to S760MPa

- Case-hardened and heat-treated steels

- Stainless and/or high-alloy steels

- Aluminum

- Copper

- Plastics

Technologically

up to date

For your individual product solutions, STIWA Advanced Products provides the latest technologies and cutting-edge laser systems:

Certified welding competence

with in-house testing laboratory

Upon request, we offer the performance of all welding work with 100% automated online seam tracking. As a certified welding manufacturer acc. to ISO 3834-2 we rely on all customary standards and go beyond them.

We apply our in-house testing processes to quickly qualify the joints in top quality and develop them further.

To this end, we use hardness testing incl. mapping, metallography, residual particle measurement, life tests, tension-compression as well as torque test stations, as well as corrosion checks.

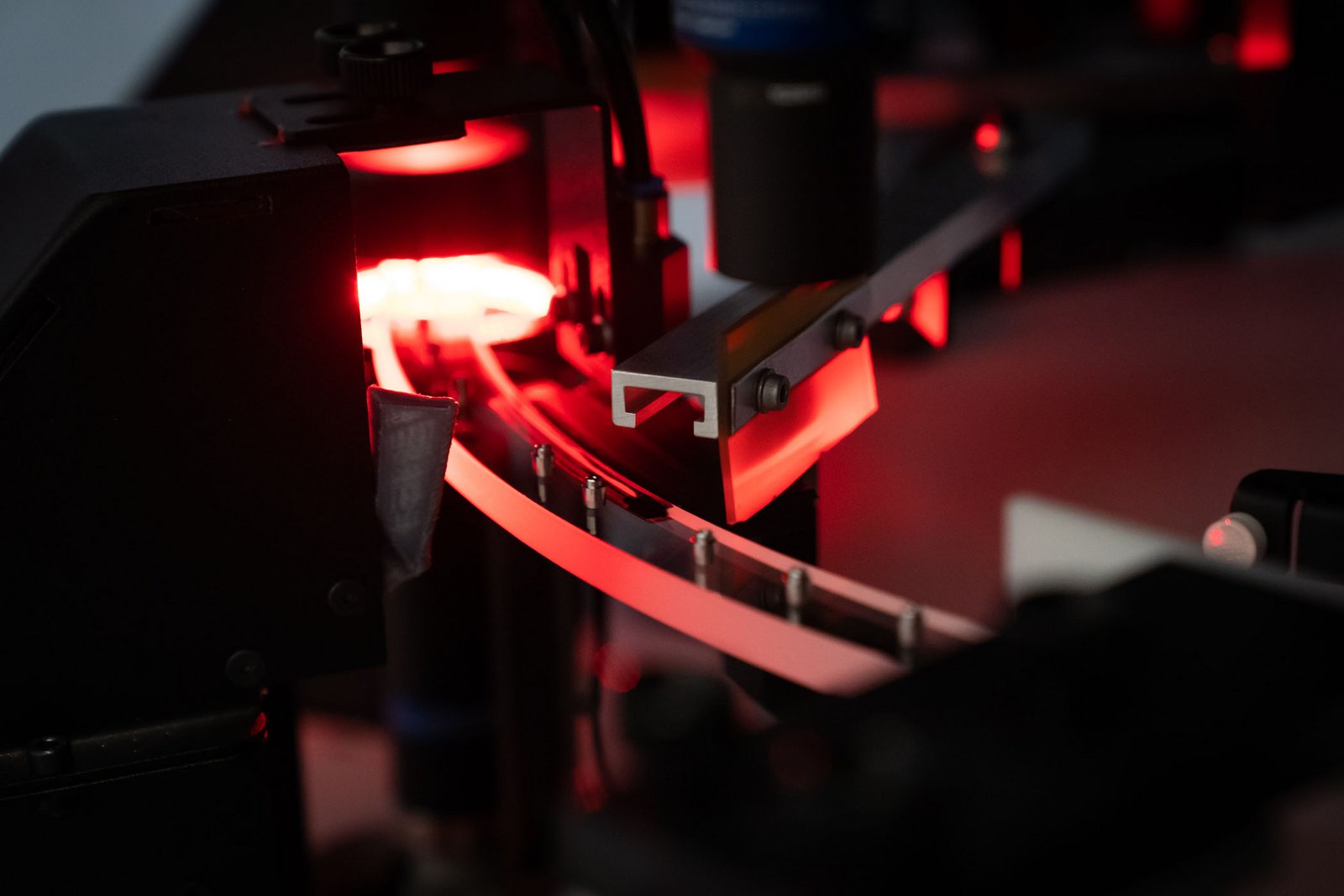

Laser hardening - establishing wear protection

due to local heat treatment

Laser hardening is a surface hardening process by means of which functional surfaces can be refined individually.

It is used to establish wear resistance exactly where necessary by inducing a microstructural change through the local application of heat.

In the process, we combine the strengths of a traditional hardening process with the advantages of minimum distortion without any need for rework.

Hardness is generated only where it is really needed!

Due to further in-house processes at our command, we can offer you a complete package from single-item manufacturing to assembly production.

Wear Protection with Laser Hardening: Precise, Distortion-Free