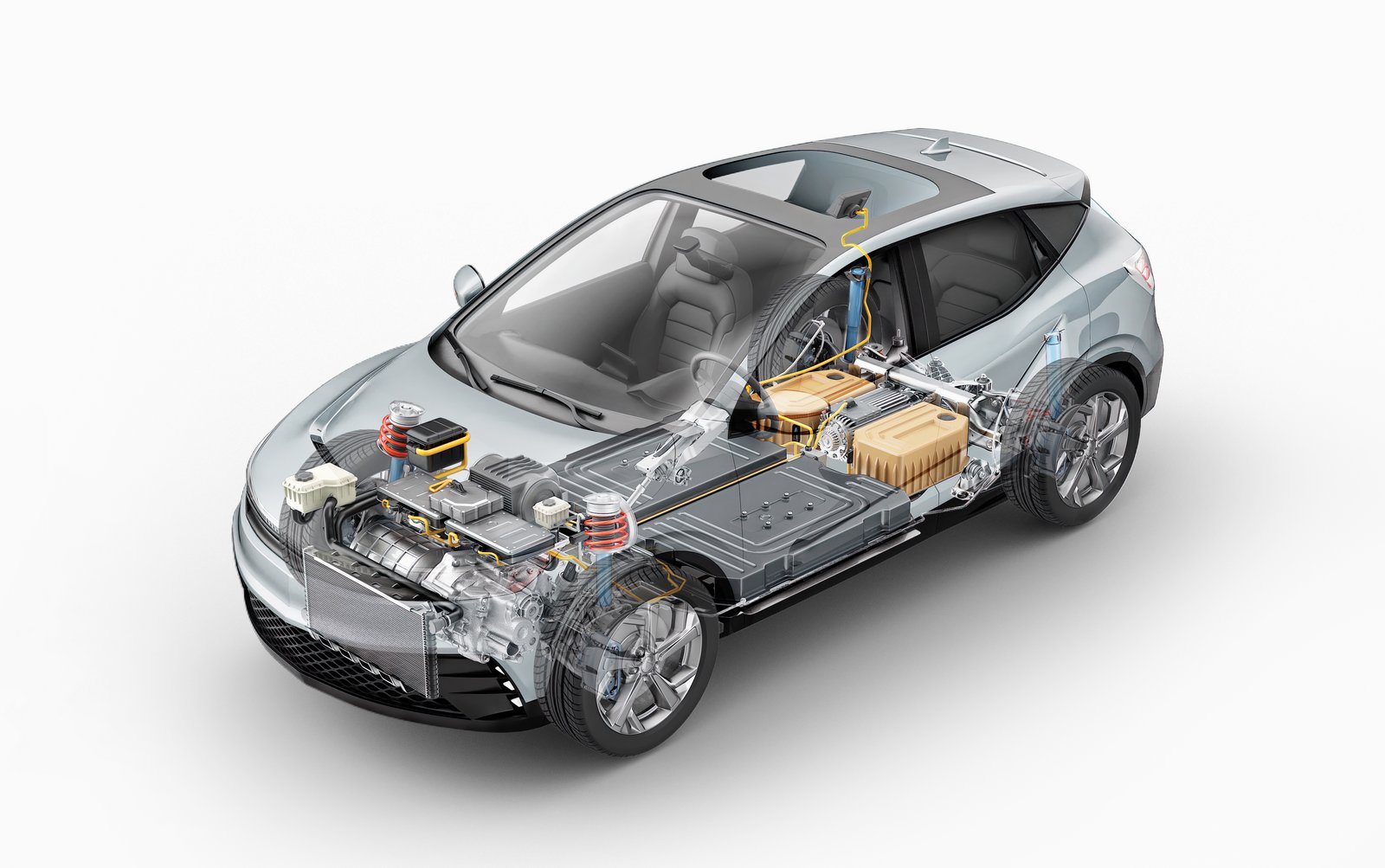

Electrification is transforming entire industries – from e-mobility and energy storage to renewable energy. STIWA is your reliable partner in this transformation: from initial concept and development to fully automated high-volume production in the millions.

Comprehensive solutions

for an electrified future.

Success starts with production-oriented product design – in close collaboration with our customers. With decades of experience in highly automated manufacturing, we develop innovative solutions for electrification and other demanding industries.

Based on target volumes, quality requirements, and cost objectives, we optimize products and production processes for maximum efficiency and profitability. By seamlessly integrating product development, automation, and manufacturing, we create a fully aligned end-to-end solution.

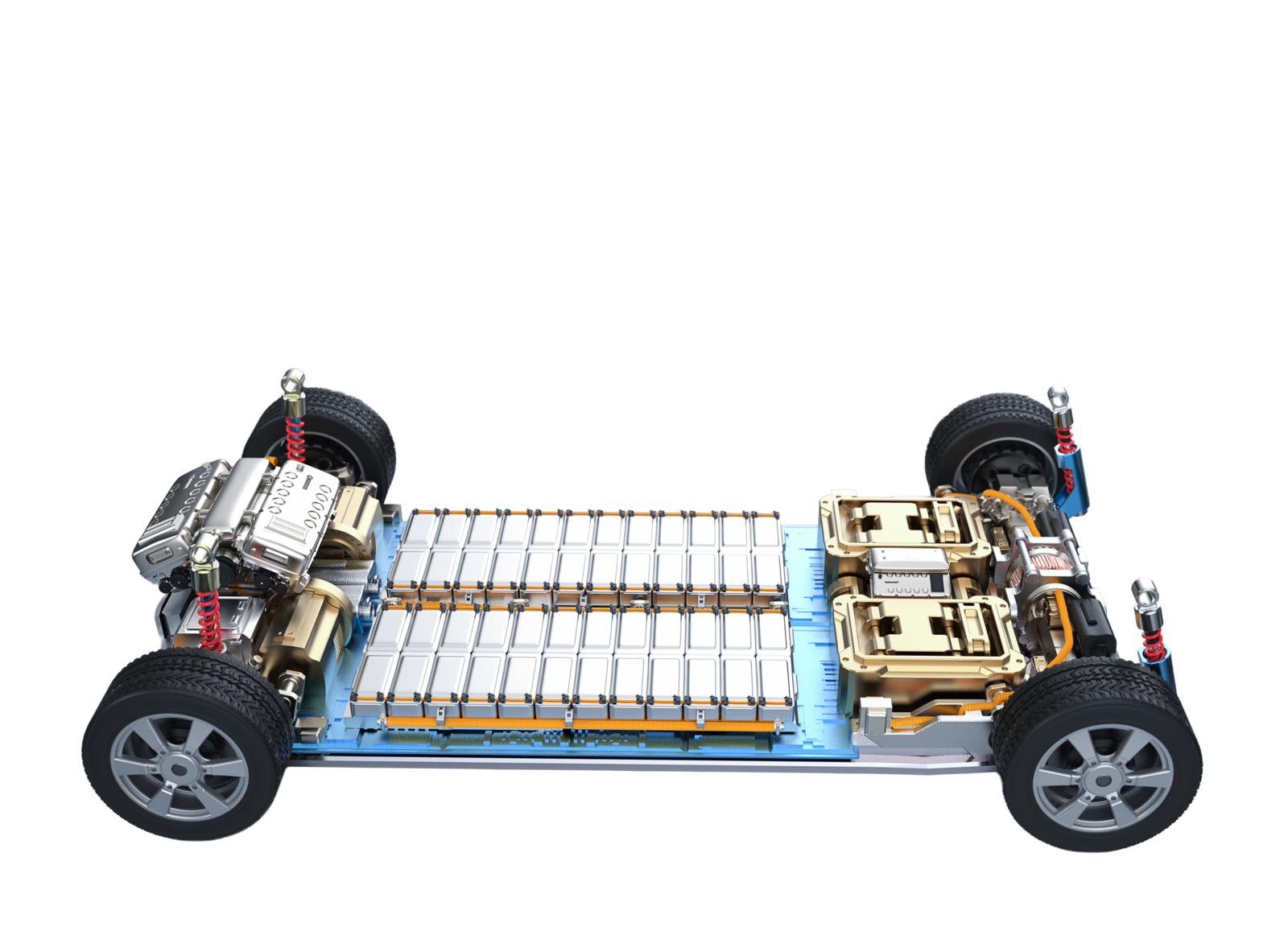

Components and assemblies for batteries and energy storage

- Innovative battery cell housings in high volumes

learn more - Busbars and contact systems for battery modules and packs

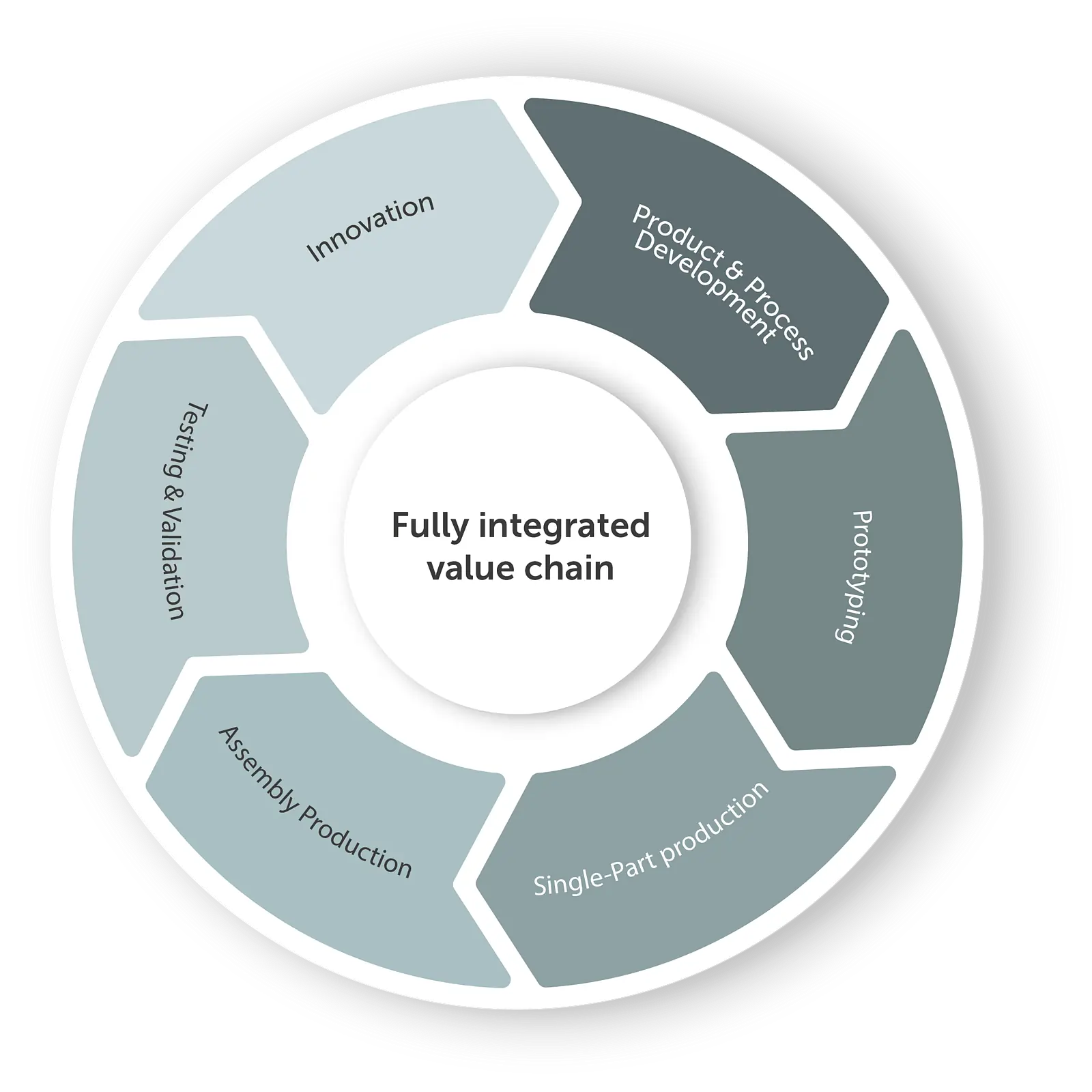

STIWAs vertical integration

From the initial idea to series production: Using state-of-the-art development, in-house prototype manufacturing, and highly automated production, we deliver precise, efficient, and future-proof solutions – all from a single source.

Within our state-of-the-art prototyping environment, including a cleanroom facility, we offer comprehensive technologies to support innovative products from development through production to extensive testing. Our testing capabilities cover mechanical stress tests, leak and burst tests, as well as electrical voltage and resistance measurements. This ensures the foundation for reliable, high-quality series products — with prototype volumes of up to several thousand units per week.

The production of individual parts – from stamped and plastic components to precision-machined parts – is carried out directly in-house at STIWA. Our deep manufacturing expertise allows us to fully understand component interactions and respond with maximum flexibility to product optimizations and changes. This enables us to quickly and efficiently meet customer requirements and technical adjustments.

Decades of experience & know-how

On more than 100 production lines, we manufacture more than 50 million products per year. STIWA Manufacturing excels in terms of maximum flexibility from small-scale series to large-scale production.

The high degree of vertical integration allows shortest feedback loops between the production of individual components and component assembly.

In the process, we rely on comprehensive, mastered in-house production technologies:

Top quality

Due to our decades of experience in the automotive supply industry and the respective quality awareness on automotive level (IATF-16949), we ensure that your products meet highest quality standards.