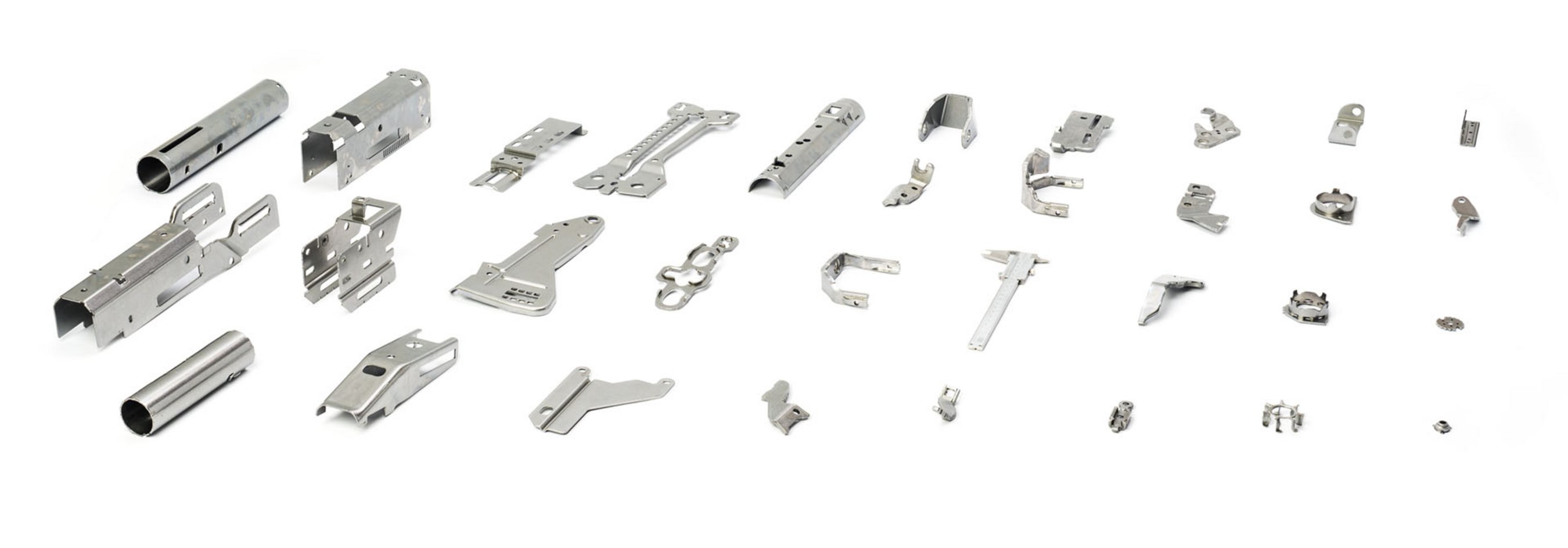

Complex die-cut parts

of high precision

With decades of experience in the production of complex forming-bending parts for customers from various industries all over the world, STIWA Advanced Products stands for premium-quality punching products from Austria and Germany - ensuring shortest lead times and cost-efficient production.

STIWA - leading in plate punching with highest quality standards and in the production of cost-efficient die-cut parts in precision-cutting quality.

Everything from one source

Due to our vertical integration and closed feedback loops from prototype development and toolmaking through to large-scale production, we are the ideal one-stop shop for each and every die-cut part meeting the highest requirements in terms of precision and performance:

no matter if your product is left to be developed or can already be manufactured, our specialists will see you through each phase of your project - from engineering to cost-efficient and high-grade serial production.

STIWA - more than 30 years of experience in toolmaking and punching

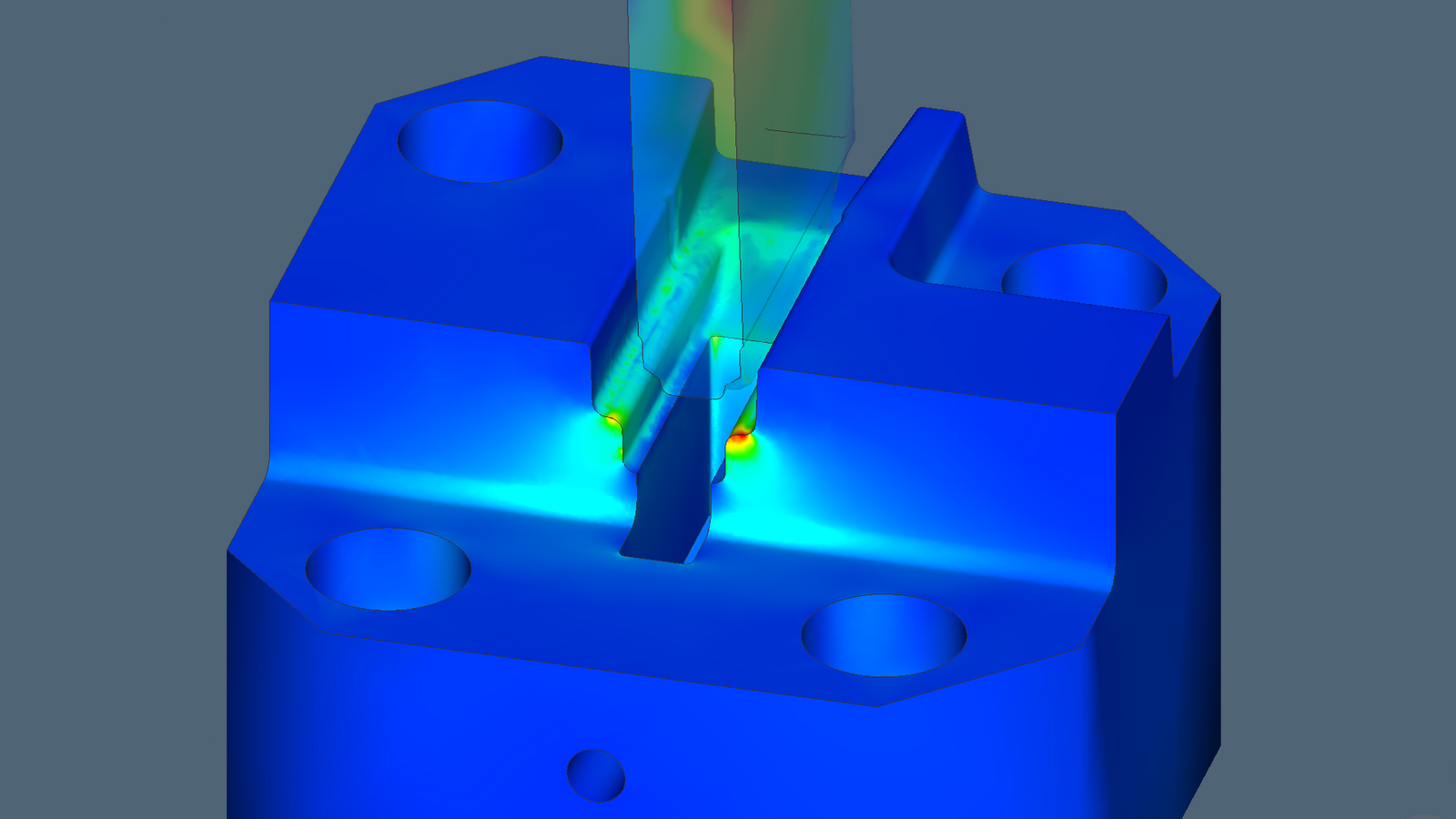

Toolmaking

With comprehensive expertise in the production of micro to macro components - from prototypes to series tools in follow-on composite transfer or compound die technology - as well as our own in-house tool testing, we stand for precision toolmaking and die-cut parts of highest quality.

Of course, we will advise you already in the design phase of your components as regards a production-friendly component design and can submit a free quotation right away.

Parts Production

Manufacture of prototypes or production on demand:

cutting-edge automated STIWA punching machines are available for each and every production requirement and deliver precision products from simple to complex components.

Due to state-of-the-art material feeding, automated production, as well as in-process functional quality control, we guarantee short processing times and cost-efficient manufacturing.

The STIWA team will be there for you with comprehensive know-how in all questions regarding punching and will provide you with further information. We will be glad to submit a first offer.

Full quality assurance

From the start, through the run, to the final inspection, we ensure seamless quality testing.

With our CAQ system (computer-aided quality assurance) we record all quality-relevant data. This includes the information from the worker self-inspection, the 3D measurement, contour graph measurement and the force/displacement measurement. In this way, we provide you with consistent quality at all times.