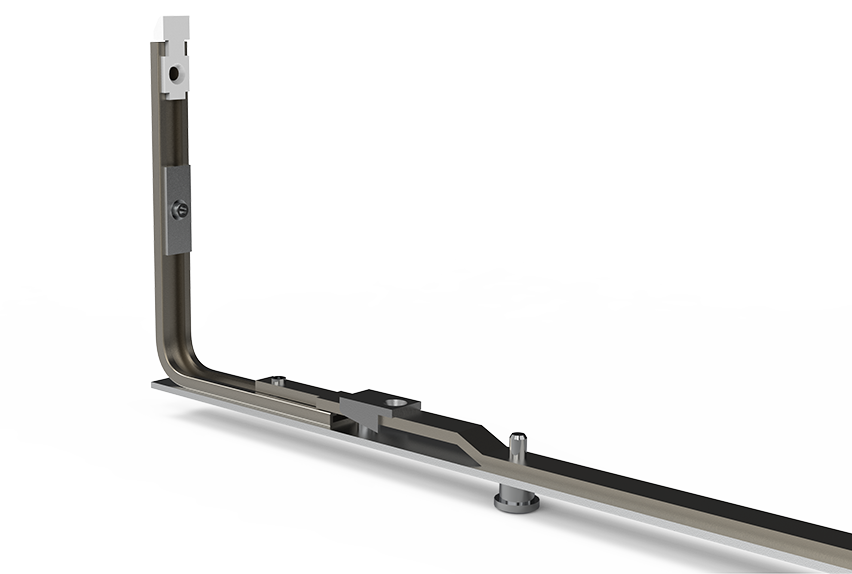

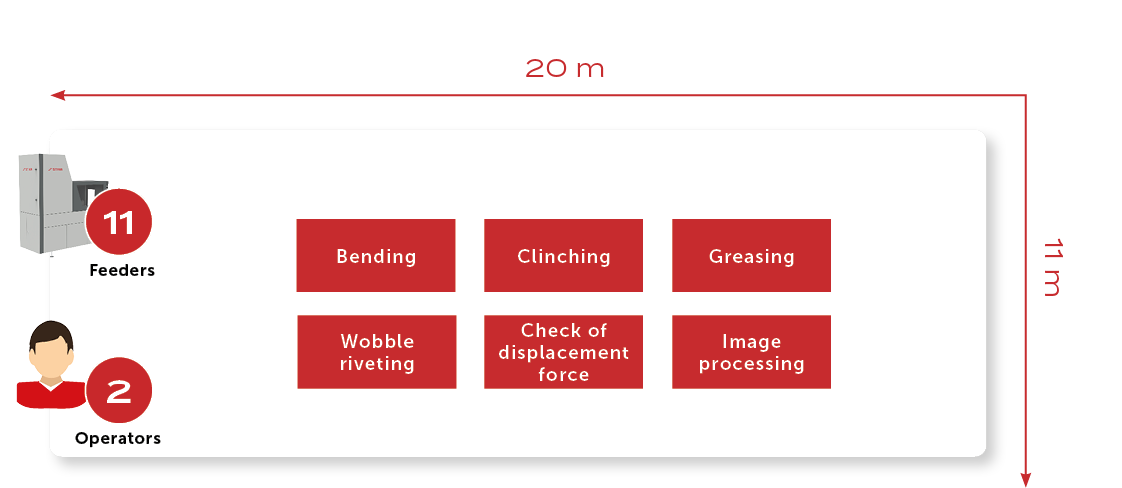

This STIWA manufacturing line produces a corner drive. These are integrated into window frames and ensure that windows are moved to the desired position when the handle is actuated

The individual parts are fed as bulk material. The steel rails are fitted via a manual workstation and bent 90° using a fully automatic bending tool. Before installing the steel belt and bolts, the components are greased. The rod, screw guide and bolt are riveted fully automatically. The finished parts are dispensed to a buffer, removed by hand and packed.