Put your passion for technology into practice.

Be part of our future.

Welcome to STIWA - your gateway to exciting career opportunities in the world of innovative technologies. As an international leader in product and high performance automation, we offer high school and university students a unique opportunity to put their passion for technology into practice.

Immerse yourself in a world of innovation, team spirit and personal development. We look forward to meeting you!

DIPLOM-, BACHELOR- OR MASTERTHESIS FOR UNIVERSITIES / UNIVERSITIES OF APPLIED SCIENCES

- Joint thesis, Bachelor thesis, Master thesis, dissertation

- Application for advertised topic or your personal proposal

- Requirement: Application letter with curriculum vitae / high school certificate / if already completed, the bachelor's certificate along with confirmation of enrollment of the current semester

- Finalization of contractual conditions incl. confidentiality agreement

DIPLOMA- / FINALTHESIS FOR HIGHER TECHNICAL COLLEGE

- Joint thesis (final project)

- Application for advertised topic

- Requirement: Application with curriculum vitae / certificate of 3. Grade (until 12/15 of the previous year) / confirmation school administration about project contents in the curriculum

- Starts usually in the course of the 1. HY of the 5. grade / cooperation via traineeship contract (with compensation of any expenses and incl. confidentiality agreement)

Your benefits

We offer a wide range of benefits to ensure a good working environment. It is very important to us that our employees feel comfortable at the workplace. This contributes to a pleasant work atmosphere and an appreciative cooperation.

Free training material

We provide free digital training materials to educational institutions such as higher technical colleges, universities of applied sciences, and universities with a focus on mechatronics & automation, as well as to pupils and students. We want to actively support the education process with realistic use cases and data sets, including simulations for virtual commissioning and AI data sets.

Exciting projects

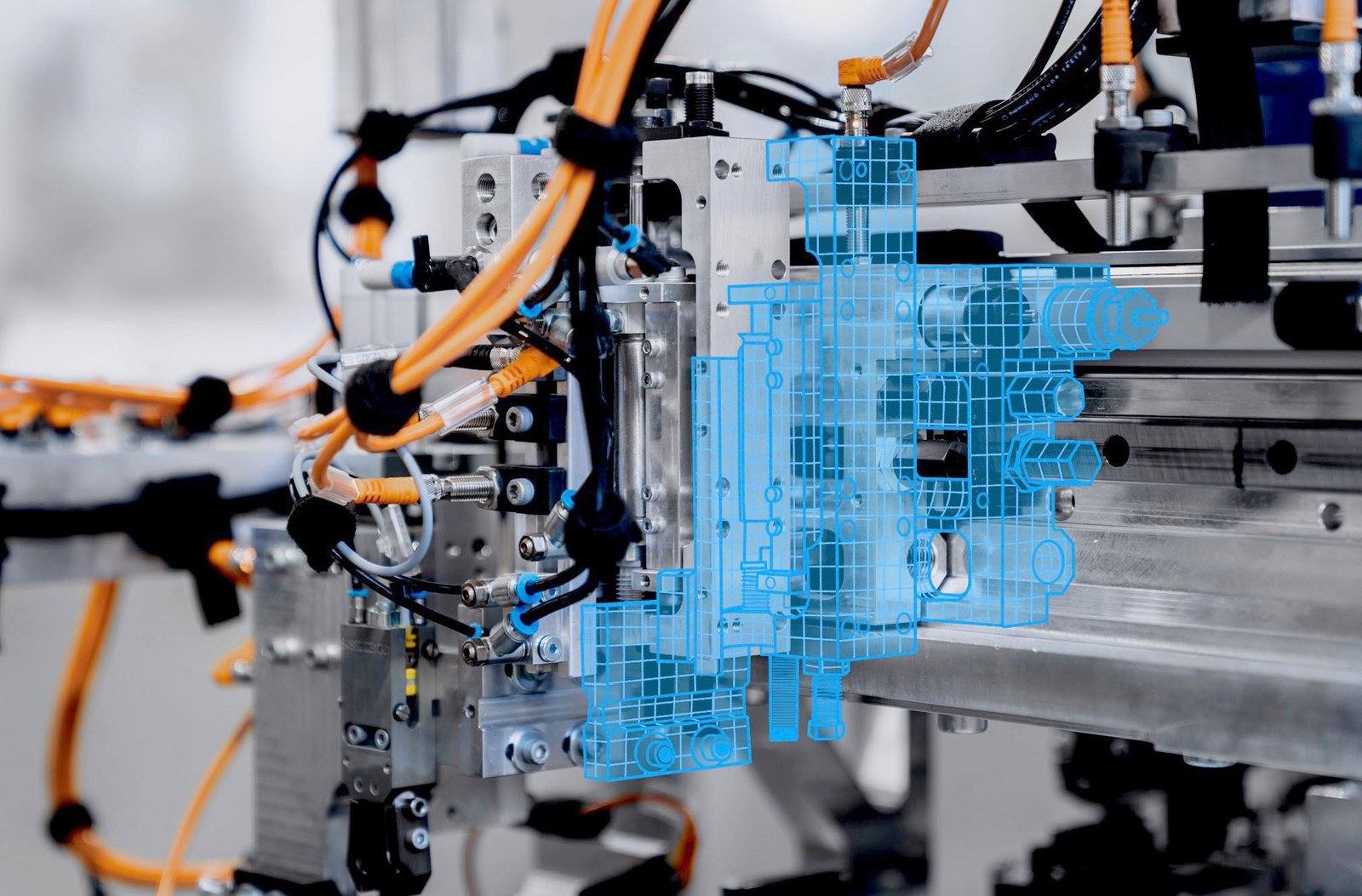

at the cutting edge of

research & technology

We have been a leader in automation, manufacturing and software for years. By cooperating with education and research, we always stay up to date. Join us! Dedicated students are always welcome to work with us on future high-tech manufacturing.

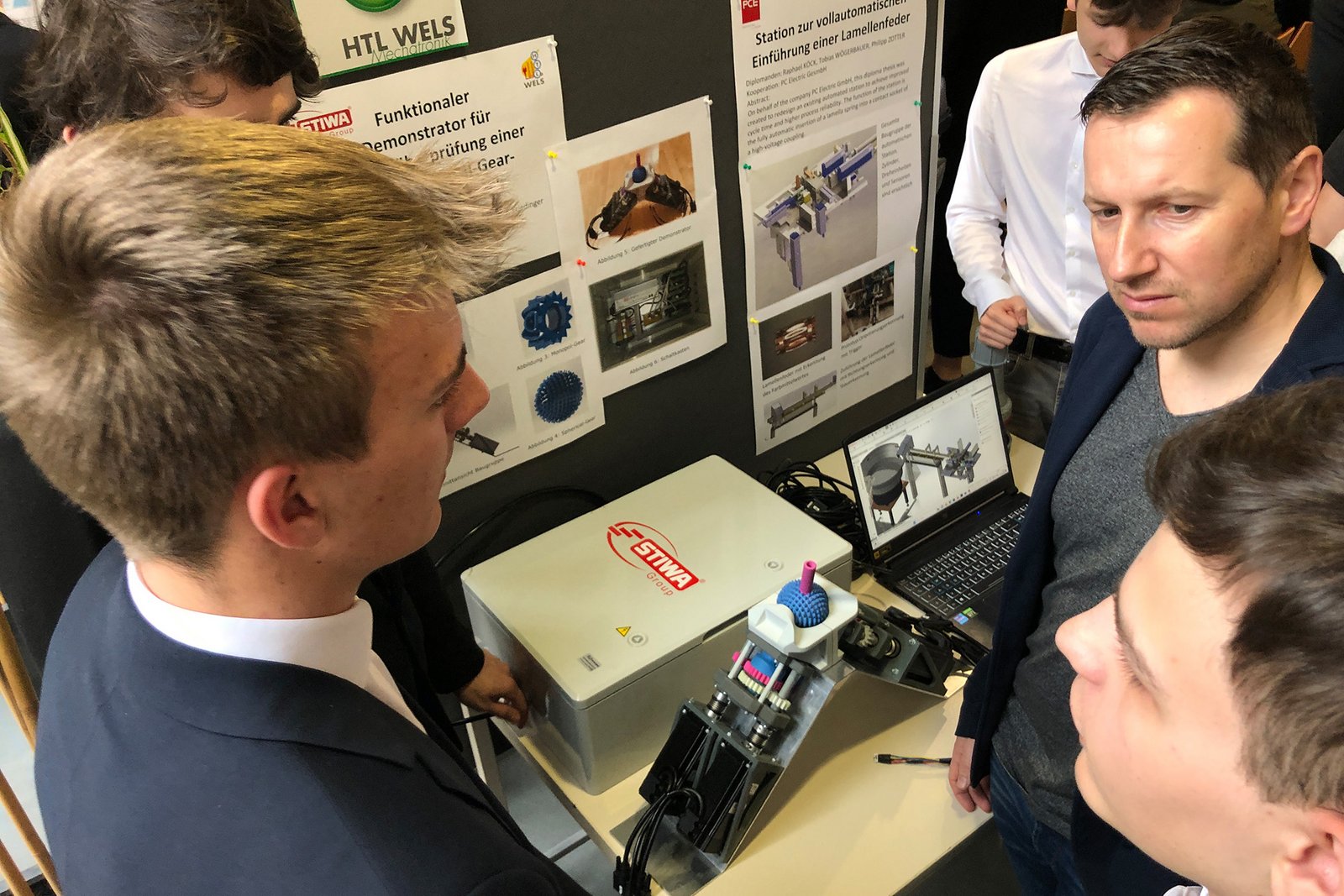

Diploma thesis of pupils at HTL Wels Mechatronics Department:

Functional Demonstrator for the concept test of a 3DOF-Spherical-Gear-Robot cinematic

Objective:

Development of an innovative demonstrator which is able to follow pre-defined and programmed points

Tasks:

- Concept test, design and construction of a drive module

- Construction of the bearing and calculation of the forward-cinematic

- Programming and selection of hardware components

Diploma thesis of pupils at HTL Vöcklabruck Mechatronics Department:

Flexible optical sorting machine for small series

Objective:

Development of a sorting machine for small series which checks quality features of the produced parts by an optical sensor

Tasks:

- Mechanics: Machine construction incl. 3D-modelling, components, assembly and optimization

- IT: PLC Programming & visualization, analogue and digital control outputs, user interface, testing and code optimization

- Electrical Engineering: Electrical plan development incl. trouble shooting, control electronic components, wire control cabinets, set and control frequency inverter

Development and evaluation of software prototypes for specific SMART maintenance problems

Motivation:

At STIWA Advanced Products (STIAP) in Gampern, we offer you the opportunity to solve real-world problems in the field of smart maintenance using software by applying state-of-the-art AI and data analysis methods, ranging from statistical models to machine learning and foundation models. We provide the ideal environment, including relevant data and systems, as well as intensive technical support. Use this to develop functioning software prototypes that will have a real impact on industry and to write an outstanding, practice-oriented thesis.

• Researching state-of-the-art technology: Analysing current AI solutions in industrial maintenance

• Identifying and solving problems: Identify STIAP-specific challenges and develop innovative software solutions

• You are studying software engineering, data science, artificial intelligence or a comparable degree programme

• Enthusiasm for Industry 4.0, data analysis and independent, solution-oriented work

• Good German and English skills

• Programming experience with Python is advantageous

Tasks:

• Real-world project: A highly topical task with direct industrial relevance

• Optimal environment: Intensive support from experts, access to production data and systems, deep insights into cutting-edge technologies

• Career boost: Gain valuable practical experience and bring your ideas to life

Objective:

• Create impact: Implement a functioning proof of concept and evaluate its feasibility and benefits

Automated test piece handling

Motivation:

STIWA Austria manufactures approximately 600,000 milled and turned parts in small batches and as individual pieces. The current quality assurance process requires the help of many employees. The testing concept, transport of test parts, and feedback of findings are labor-intensive processes that depend on employees.

Tasks:

- Create an automation concept for the 3D coordinate measuring machine.

- Create a concept for the automated transport, storage, and handling of test parts.

- Develop a concept for providing feedback on measurement rejections to machine operators.

Objectives:

- Evaluation and presentation of a solution for subsequent changeover of the entire machinery

- System proposal for new installation of a new manufacturing site (new building onto the green field)

- Worldwide operation in the STIWA Group Business area Manufacturing

You would like to write your thesis/final project at STIWA,

but there is no topic available for you at the moment?

Then send us your application

or an individual topic by e-mail.

We offer pupils and students exciting insights into our many careers. You will have the opportunity to get involved and develop both professionally and personally. Whether it's an internship or an academic thesis, we'll give you a solid foundation for a successful career.

Daniela Kaml

Human Resources