Business unit

Automation

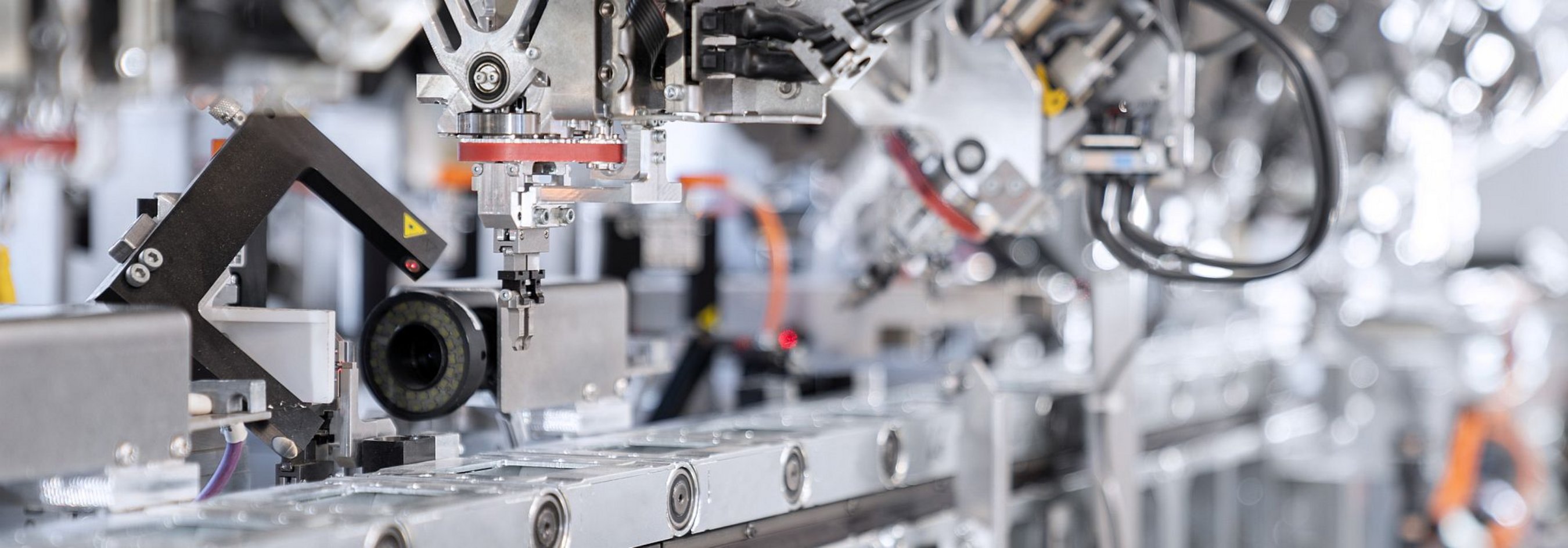

From the product idea to automated serial production

As a specialist for high-performance automation, STIWA stands for complete solutions in mechanical engineering. Fast conveyor systems, flexible assembly and process modules, as well as intelligent software solutions are the foundation for efficient production.

Services:

- Engineering in advance – starting with product and process development – in order to develop the best machine and production concept

- Integrated technology and overall responsibility as the general contractor

- Fast conveyor systems, standardized components and intelligent software solutions (starting control, control station, analysis)

Business unit

Advanced Products

From the idea to the innovative serial product

As a global development and competence center for product and production technologies, STIWA implements innovative product ideas from the prototype to large-scale production. Development, industrialization and serial production within the company are the base for cost-optimized implementation in top quality.

- Close interaction between development, process technology and manufacturing

- Efficient assembly in short cycle time

- Innovative manufacturing technologies (e.g. laser applications) as well as different base production types (e.g. punching and machining)

- Integrated quality management

Business unit

Manufacturing Software

Manufacturing software enables detailed technical analyses in multiple steps of the project as internationally operating manufacturer and system integrator of standardized software solutions. They serve as a base for a continuous optimization of the processes with the goal to raise productivity.

Optimized production through connected and controlled processes:

- Adjustment of manufacturing processes in real-time

- Effective engineering tools and software solutions with maximum consistency

- Consistent and sustainable competitive advantages through fully integrated standardized processes

Business unit

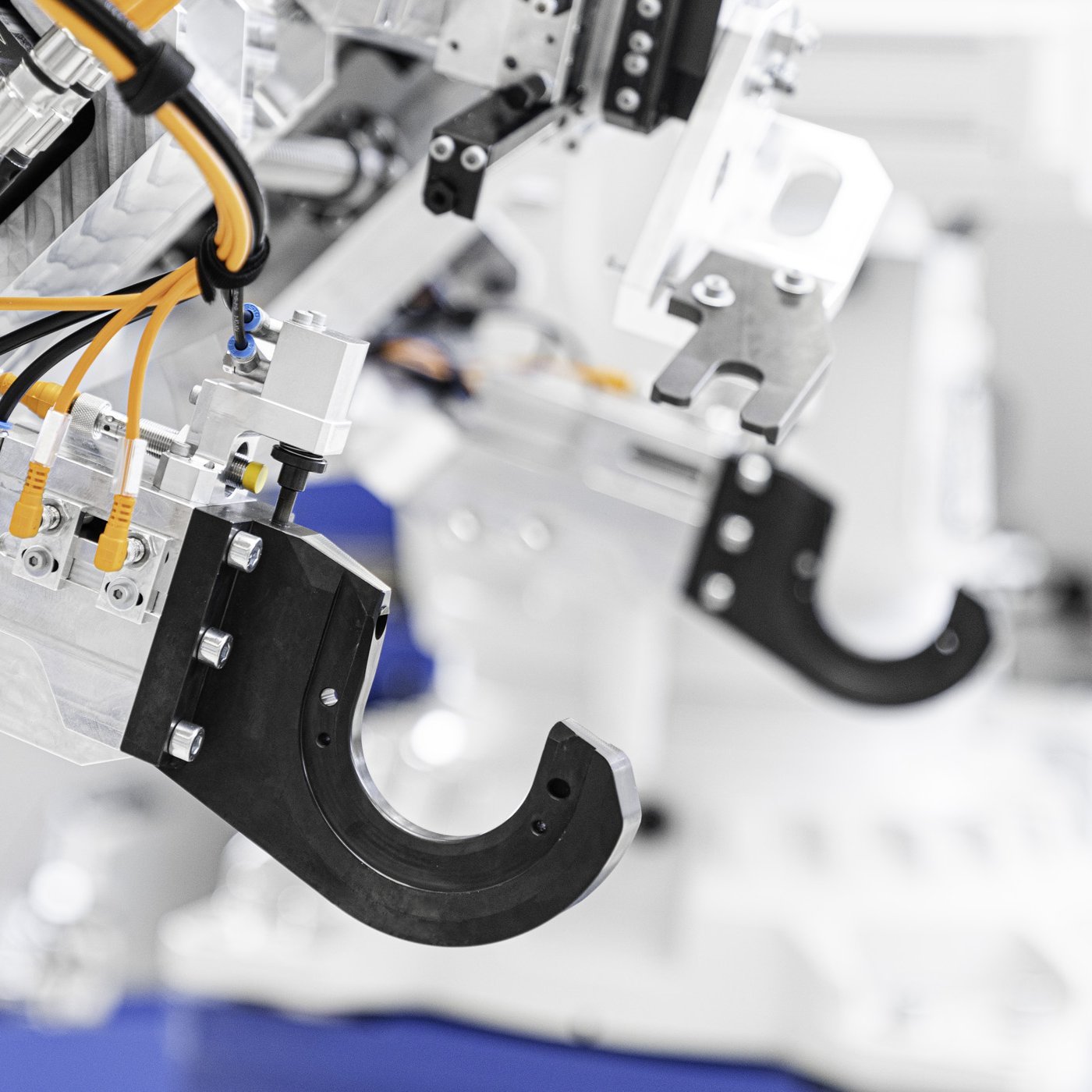

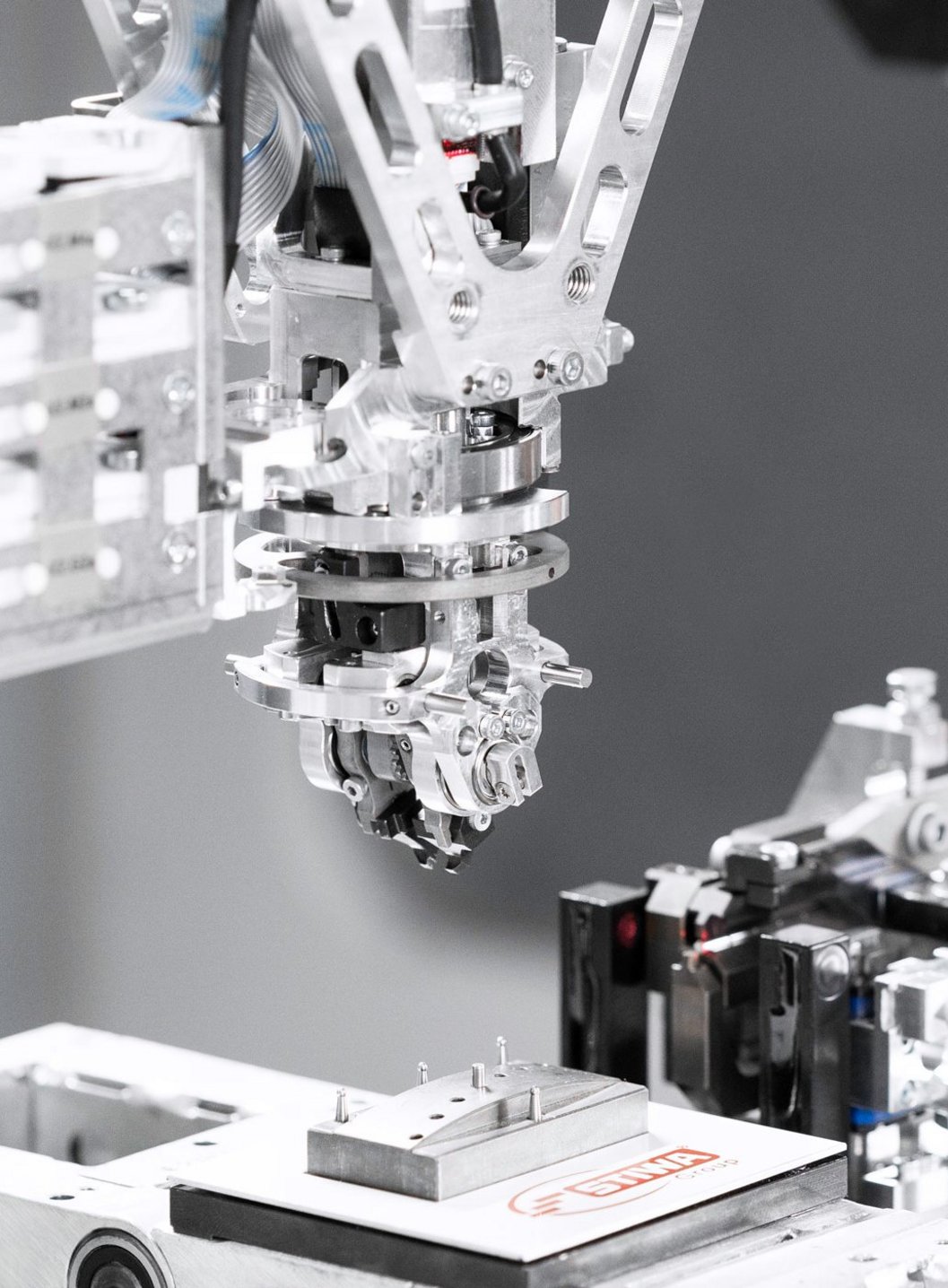

Mechatronic Systems

Technology making an impact

With years of experience in manufacturing automation facilities and the development of mechatronic systems required for this, STIWA Group offers modern automation components to ensure maximum flexibility and security.

- High scalability and comprehensive standardization of mechanical and software processes

- Optimized technology and system integration: Parameterizable, integrable, adaptable and fast

- The greatest possible flexibility, quality and security while also being reusable and at the lowest overall costs

- Optimal processes with maximum impact

Business unit

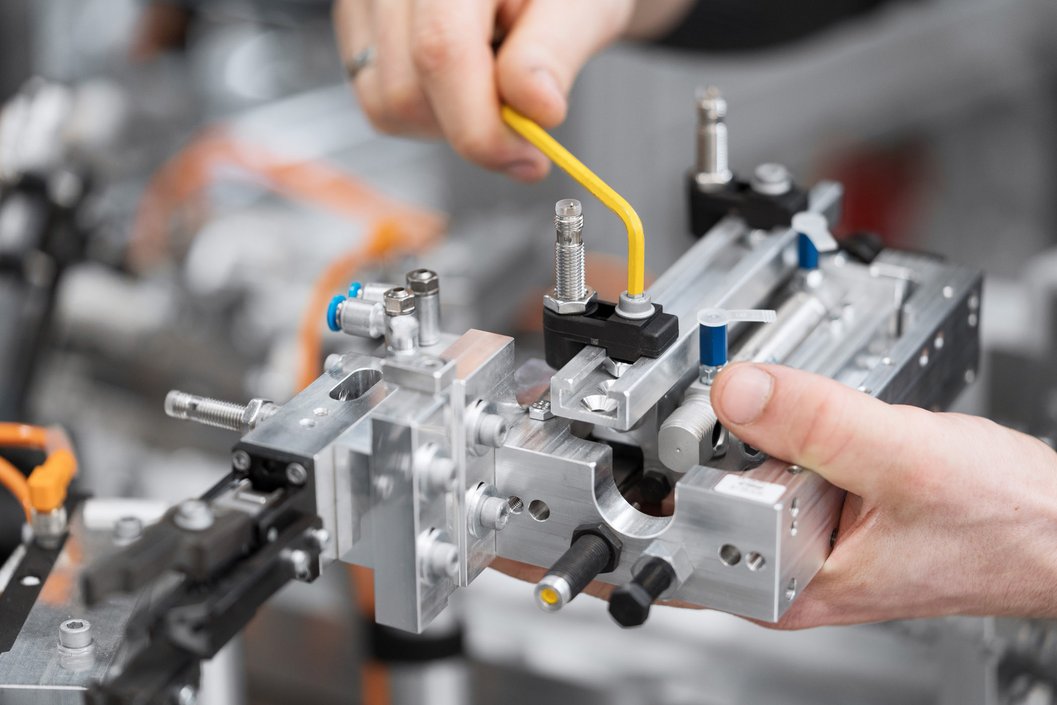

Machining

Competence through in-house manufacturing – machining with an availability warranty

Machining production with the highest precision – from complex individual components to large-scale production – is a core competence of the STIWA Group. The base for high-quality at low overall costs:

- High degree of automation

- Process development

- Versatile processing technologies

- Use of specialized programing software

- Consistent quality assurance

The result: High-quality, cost-effective parts with short cycle times

Business unit

After Sales

From mechanical engineering to production excellence

With comprehensive support throughout the entire manufacturing period, STIWA ensures that its worldwide customers can rely on competent support at any time. This is the base for stable production at the highest standard.

Services:

- A multi-stage four phase model which will guarantee optimal transitions from project planning to use of the machine

- Comprehensive support across the entire manufacturing period and preventative monitoring of indicators and system parameters

Business unit

Building Automation

Using limited resources sustainably

The Business Unit Building Automation develops energy-efficient buildings while guaranteeing as much flexibility as possible. Total energy costs are reduced by up to 30% by the intelligent networking of production plant, logistics, building technologies and energy systems.

Productivity growth through:

- Engineering for buildings and production processes

- Joint management of all material and energy streams

- Identification of potential efficiency savings by means of production and analysis software

Areas of application: Offices, manufacturing plants, logistic and business centers, hotel industry, sports facilities

Business unit

PREANALYTICS

From diagnosis to reliable results

Through targeted mechanization, the use of standardized software, and the development of intelligent logistic processes, STIWA ensures fully automatic and continually traceable laboratory processes according to industrial standards in each and every laboratory.

From diagnosis to reliable results:

- Targeted mechanization

- Use of standardized software

- Development of intelligent logistic processes

This year alone, more than 15 million samples have been processed by STIWA automated laboratories.