30 % more energy-efficient production buildings,

maximum flexibility

Through intelligent networking of your production machines, logistics, building technologies and energy systems we are able to reduce total energy costs by up to 30%, while simultaneously increasing productivity. In addition, we are promote independence from gas and oil through the use of waste heat and alternative supply concepts. Based on years of experience with companies in the production industry, we realize an optimal production environment today in individual projects as well as in cooperation with exporting companies or general contractors in construction. The integral planning from the start of the project to its acceptance and guidance during running operation ensure that the set goals can be reached together.

The company building

as a machine

We see your building as a machine – aiming to optimize efficiency. Together we design optimal operating procedures and holistically develop the building from the inside out. We create tailor-made solutions for both greenfield and brownfield sites, whether the building is new or existing.

Throughout the implementation we rely on control across all disciplines based on Beckhoff, as well as many years of reliable cooperations in architecture, subject and project planning. It is our goal to create an environment that increases the productivity of our customers, and at the same time significantly reduces the use of resources like personnel, materials, and energy.

From integrated planning to

optimal operation:

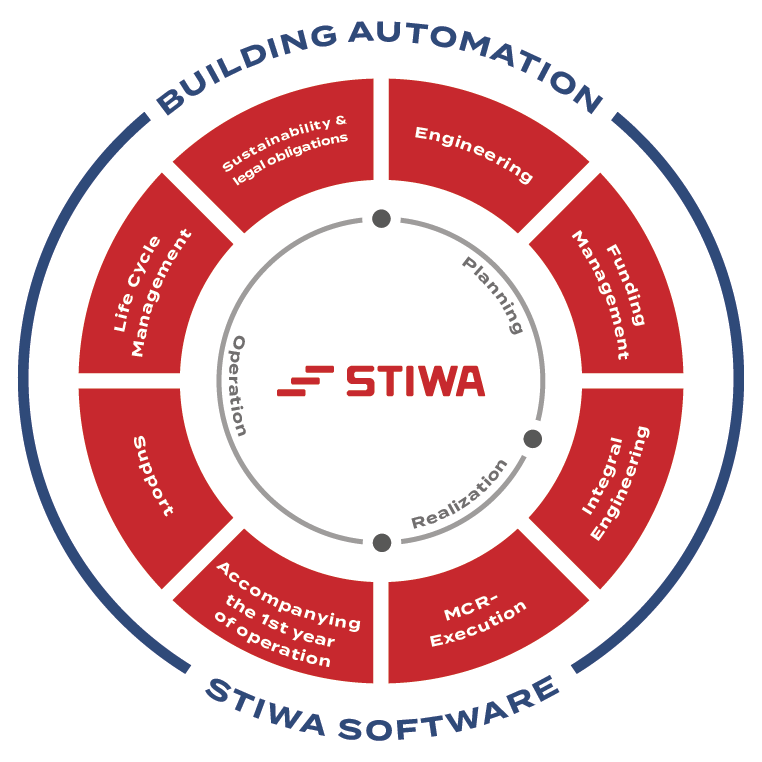

From project inception to acceptance, we provide continuous support to ensure that set goals are achieved. A well-coordinated team of experts from various disciplines will work with you to develop the best solution. Specialists in diverse fields such as building technology, automation, architecture, logistics, energy, and process management contribute their expertise to make your building efficient and future-proof.

Your Partner for the

Entire Lifecycle

We provide end-to-end support throughout the entire lifecycle of your manufacturing facility. From initial planning to the realization phase and ongoing operations, we guide you every step of the way. In doing so, we ensure compliance with legal and sustainability standards while continuously optimizing your energy flows and processes to future-proof and maximize the efficiency of your production.