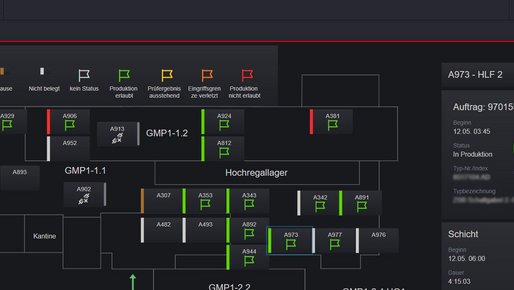

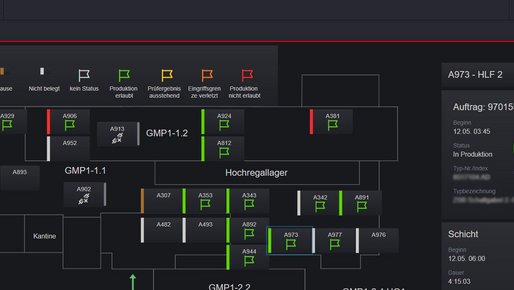

Maximale Transparenz und Effizienz in der Qualitätssicherung

Die Möglichkeit, alle relevanten Daten auf einen Blick zu erfassen und zu analysieren, erlaubt es, die Produktion transparenter, effizienter und…

Shopfloor Analytics und Business Intelligence (BI) für nachhaltige Produktivitätssteigerung

Umfassende Analysemöglichkeiten garantieren eine transparente Produktion über den gesamten Lebenszyklus von Anlagen. Unsere Lösungen setzen bereits beim Maschinenbau und in der Hochlaufphase an und ermöglichen neben dem schnelleren Ramp Up auch eine kontinuierliche und nachhaltige Steigerung der Produktivität – ortsunabhängig.

Unser Ziel – gemeinsam mit unseren Kunden – ist Produktionsexzellenz in allen Bereichen (Leistungseffizienz, Verfügbarkeit, Qualität). Dafür stehen neben vielfältigen vorgefertigten Analysewegen (über Dashboards) auch Editoren zur Verfügung, um eigene Sichten, Dashboards, Analysewege uvm. zu gestalten – „built in“ in unseren webbasierten Produkten.

Vom Anlagenbediener bis zum Management haben unsere Kunden ihren Produktionsprozess immer im Griff und wissen, was sie morgen machen müssen, um ihren Wettbewerbsvorsprung zu halten und weiter auszubauen.

GEFÜHRTE ANALYSEWEGE

250+ vorgefertigte Dashboards und Reports

INDIVIDUELLE ANALYSEN

INDIVIDUELLE DASHBOARDS

AUTOMATISCHER BERICHTSVERSAND

für regelmäßige Analysen

OFFENE STANDARDS UND SCHNITTSTELLEN

Die Möglichkeit, alle relevanten Daten auf einen Blick zu erfassen und zu analysieren, erlaubt es, die Produktion transparenter, effizienter und…

Datengetriebene Lösungen schaffen größtmögliche Effizienz im Nacharbeitsprozess. Für Knorr-Bremse ist dies ein ganz wesentlicher…

Was uns verbindet? Wir lassen Knorr Bremse selbst sprechen!

Zur Steigerung der Anlageneffizienz einer ihrer Produktionsanlagen wurde bei FESTO ein interdisziplinäres Team um Anlagenhersteller, Produktionsteam…

Zur Steigerung der Anlageneffizienz setzt die Valeo Wischersysteme GmbH auf Software-Know-how aus dem Hause STIWA: AMS Analysis-CI heißt das…

Dipl.-Ing. Michael Meisel

Bereichsleiter Vertrieb und Produktmanagement

STIWA Software