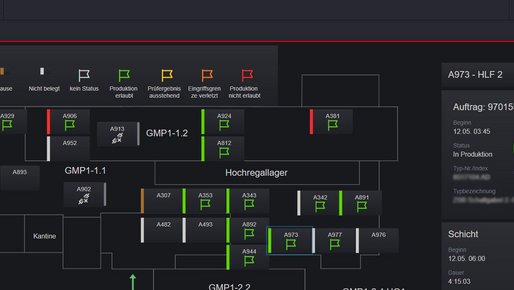

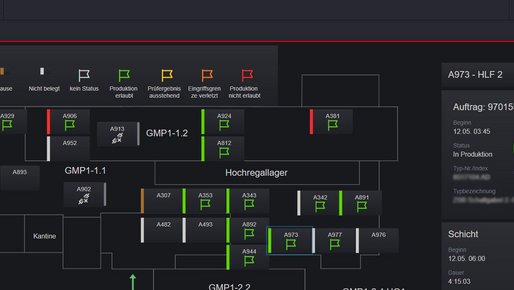

Maximum transparency and efficiency in quality assurance

By being able to record and analyze all relevant data at one glance, production processes become more transparent, efficient and consistent.

Shopfloor Analytics and BI for sustainable increases in productivity

Comprehensive analysis options guarantee transparent production over the entire life cycle of plants. Our solutions start with the mechanical engineering and the ramp-up phase, and enable not only a faster ramp-up, but also a continuous and sustainable increase in productivity – independing from the location.

Our goal – together with our customers – is production excellence in all areas including performance efficiency, availability, and quality. In addition to a variety of predefined analysis paths (via dashboards), editors are also available for designing your own views, dashboards, analysis paths, etc. built-in to our web-based products.

From machine operators to management, our customers always have their production process under control and know what they need to do tomorrow to maintain and further extend their competitive edge.

GUIDED ANALYSIS PATHS

250+ prefabricated dashboards and reports

INDIVIDUAL ANALYSES

INDIVIDUAL DASHBOARDS

AUTOMATIC REPORT DISPATCHING

for regular analyses

OPEN STANDARDS AND INTERFACES

By being able to record and analyze all relevant data at one glance, production processes become more transparent, efficient and consistent.

Data driven solutions create maximum efficiency in the rework process. For Knorr-Bremse this is an essential quality control process at their plant on…

What connects us? We let Knorr Bremse talk for themselves!

In order to increase the efficiency of one of its production machines, FESTO has set up an interdisciplinary team including the plant manufacturer,…

To increase efficiency of its machines, Valeo Wischersysteme GmbH relies on software know-how made by STIWA: The analysis tool is called AMS…

Dipl.-Ing. Michael Meisel

Head of Division Sales and Product Management STIWA Software