Maximum transparency and efficiency in quality assurance

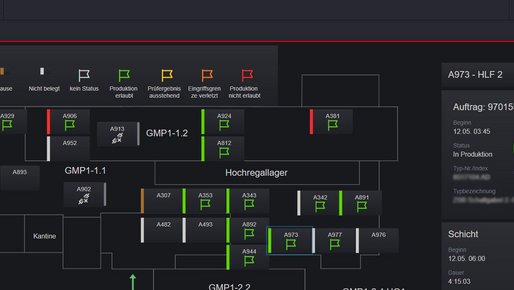

By being able to record and analyze all relevant data at one glance, production processes become more transparent, efficient and consistent.

ENABLE YOUR PRODUCTIVITY

We bring transparency to the shopfloor, support sustainable productivity increases, and offer a flexible control system for your heterogeneous machine platform.

For over 30 years, many market leaders in various industries have relied on our Shopfloor software. Due to STIWA Group’s unique combination of automation, software, and production prowess, our Shopfloor monitor solution is truely unlike anything else.

We know the problems of our customers. By optimization of rework and reducing rejects by increasing machine efficiency (OEE), by shortening machine ramp-up times and improving cycle time.

Our high performance and scalable analysis tools are highly configurable and provide essential tools used to optimize machine performance, availability, and quality. From individual machines, to a fully digitalized Shopfloor.

STIWA – Shopfloor Software for the production of tomorrow

Producing sustainable and efficiently is an essential competitive factor, and is the basis for successful economic growth. In Europe, in particular, the most successful production facilities are those that process complex products with low manpower, in four shifts, and with the help of new integrated technologies in short setup cycles in an automated and process-reliable manner. Interconnecting the Shopfloor, from the sensor to the cloud, is becoming more indispensable than ever.

We are pioneers in the digitization of Shopfloor processes with a focus on assembly systems for manufacturing highly complex assembly groups. We use data from all available sources from upstream processes such as a base production or pre-assembly to information from quality laboratories, logistics and IT – combined with our comprehensive industry know-how as a plant manufacturer and operator. We pick up the data where it originates and, thus, form the structure for the visualization, optimization and control of your Shopfloor.

Transparency and secure decisions in your Shopfloor

ShopfloorBI and Analytics for sustainable increase of productivity

Multi-vendor control station for reliable processes for heterogeneous machine parks

We pick up the data where it originates.

OT, IT and M2M Connectors

In-depth industry know-how for the acquisition of measurement and process curves as well as micro standstills

Without the AMS Analysis-CI we’d not have achieved what we have today - namely a transparent, reliable, and controlled production. By means of AMS-Analysis CI, we could reduce our ramp-up time by 30 to 40 percent!

Peter Nieslon

Manager Industrial Engineering Valeo Wischersysteme GmbH

Within a few weeks, the OK output of the plant was increased by more than 10 %. The reject rate was reduced significantly. After one year, the rate of increase of OK output already stood at 40 %.

Kilian Seiler

Project manager Festo AG & Co. KG

The AMS Analysis-Cl we developed together with STIWA Group is running very promisingly for us. We expect an improvement of the functional-test-failure-rate by 30 percent from it.

Gerhard Schwarz

Plant Manager at Knorr Bremse in Aldersbach

How we generate benefits: Our success stories give insight to current customer projects.

By being able to record and analyze all relevant data at one glance, production processes become more transparent, efficient and consistent.

Data driven solutions create maximum efficiency in the rework process. For Knorr-Bremse this is an essential quality control process at their plant on…

What connects us? We let Knorr Bremse talk for themselves!

Always close to the machine, we offer our customers extensive opportunities in terms of data driven decision making and data transparency at the production machine as well as globally networked across all locations. We digitize the discrete manufacturing and bring transparency to the Shopfloor.

Dipl.-Ing. Michael Meisel

Head of Division Sales and Product Management STIWA Software