Gira: transparency is key

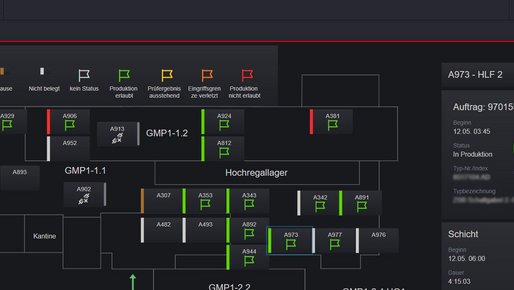

With ever larger and more complex production networks, transparency is an essential building block to achieve sustainable and efficient production…

References & projects in the manufacturing & production optimization

Our goal is to generate immediate benefits and thus increase the competitiveness of our customers.

Will we be successful with this? Our customers can best answer that!

With ever larger and more complex production networks, transparency is an essential building block to achieve sustainable and efficient production…

By being able to record and analyze all relevant data at one glance, production processes become more transparent, efficient and consistent.

Data driven solutions create maximum efficiency in the rework process. For Knorr-Bremse this is an essential quality control process at their plant on…

What connects us? We let Knorr Bremse talk for themselves!

Defective feeding material that leads to increased rejects, incorrectly set screwing processes, that block the workpiece carrier for a long time and…

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/_processed_/c/7/csm_Produktfoto_LTM-CI_Kompaktautomation_3000x2000_PS_2019-01-25_S1A00814_2b18ea0c79.jpg)

Continuous development of the software, uniform software standards and the same user interface - with STIWA Manufacturing Software maintenance various…

In order to increase the efficiency of one of its production machines, FESTO has set up an interdisciplinary team including the plant manufacturer,…

To increase efficiency of its machines, Valeo Wischersysteme GmbH relies on software know-how made by STIWA: The analysis tool is called AMS…

To optimize their production processes and increase machine efficiency significantly, Festo AG capitalizes on Manufacturing Software from STIWA.

Mag. Alexander Meisinger, MSc

Head of Customer Success Management