STIWA at the Battery Show 2025 in Detroit

STIWA Group is your partner for innovative battery cell components and highly automated battery production solutions. As the first European company to secure a serial nomination for prismatic battery cell cap-assemblies (30+ million parts/year), we set new benchmarks in cost efficiency and technological excellence.

From development to high-volume production – with in-house technologies like stamping, laser welding, injection molding, and high-speed assembly, STIWA ensures top quality at the lowest total cost of ownership. Our high-speed production lines and integrated software solutions deliver maximum efficiency – globally supported by 12 locations worldwide.

Let’s discuss your current projects – visit us at the The Battery Show or schedule a meeting for a personal meeting!

Our mission

Complete solutions from a single source:

STIWA Automation, STIWA Manufacturing and STIWA Software

STIWA Automation

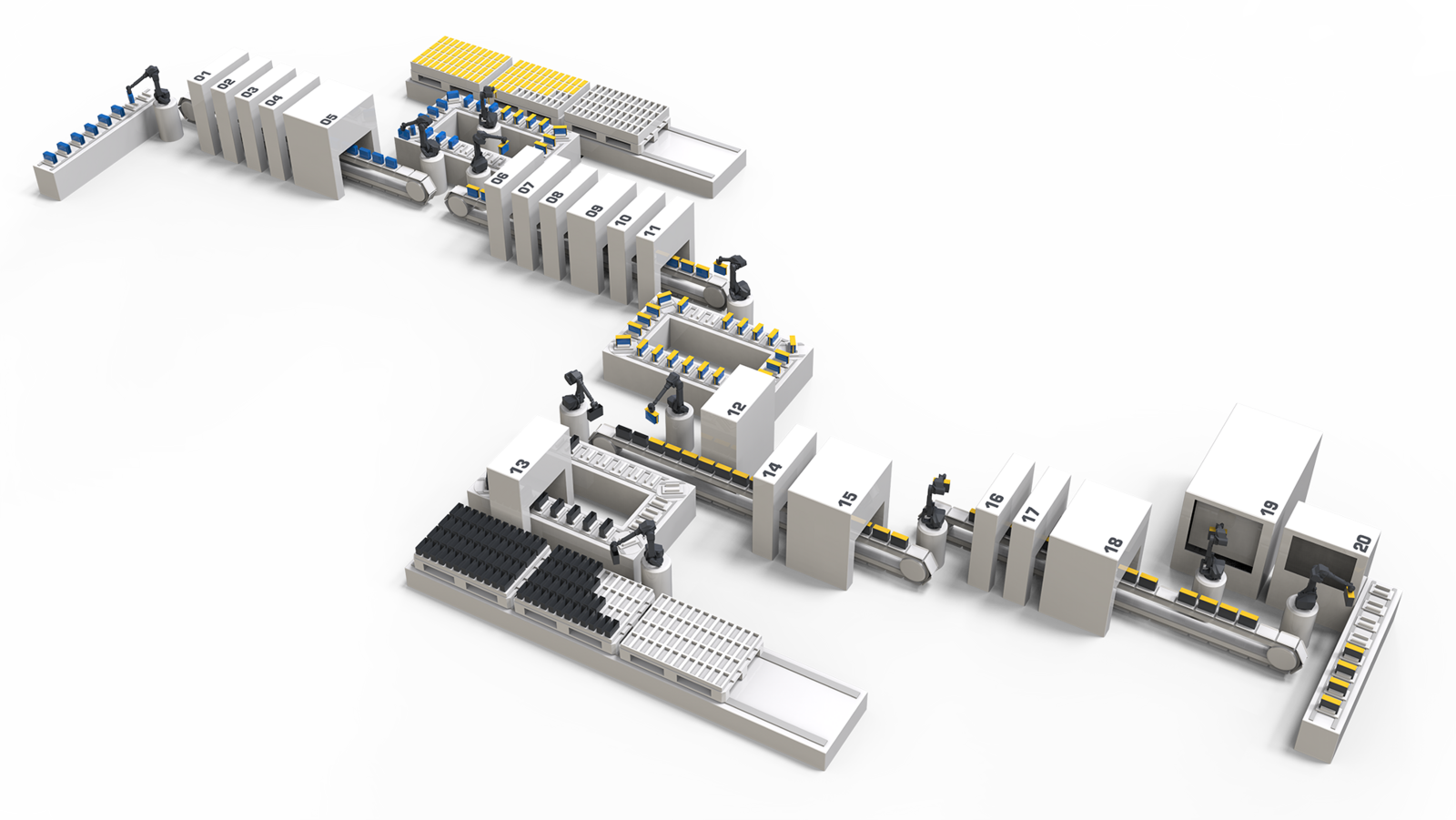

Leading specialist for assembly lines in the field of high-performance automation

Do you want to push your battery cell production to the next level? Do you want to move to the fast lane in module and pack assembly? Do you need fast cycle times, fully automated production solutions, and completely integrated processes and technologies? Then STIWA Automation is THE company to look out for.

STIWA Manufacturing

Battery-cell housing solutions

Your development partner from the first idea to million-scale production

STIWA Manufacturing specializes in development and high-speed production of battery-cell housings (cap assemblies) and battery-related components, efficiently transforming innovative ideas into serial products. With in-house development, industrialization, and production, we provide cost-optimized manufacturing processes. Leveraging advanced technologies like stamping, laser welding, injection molding, and high-speed assembling, we ensure highest performance.

We are the only European company with a series nomination in this field. Our extensive value chain, autonomous production, and focus on innovation enable us to stay competitive against Asia. Throughout all our processes, we always focus on the lowest TCO, ensuring maximum efficiency and cost-effectiveness for our customers.