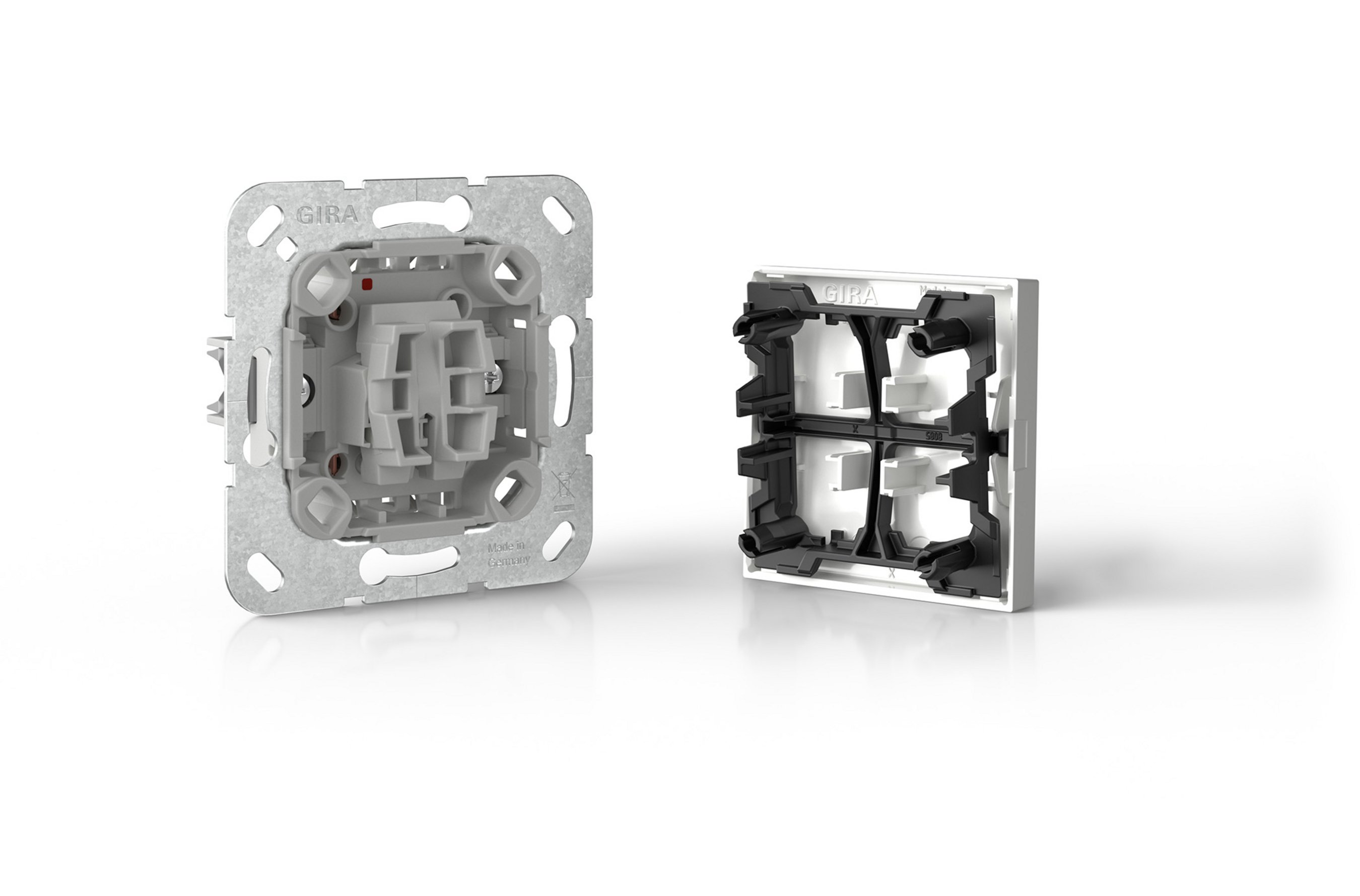

Gira is primarily associated with switches - which score points for their excellent design, functionality and durability. But the company offers much more, above all: future-oriented solutions. By investing in innovative production technologies, the German family-owned business has remained internationally competitive since it was founded 120 years ago. These days, STIWA automation solutions play a key role in this.

Gira Giersiepen GmbH & Co. KG, which was founded in 1905 and is based in Radevormwald, Germany, employs more than 1,250 people. With representatives in 40 countries, it is one of the leading full-service providers of intelligent system solutions for electromechanical and networked digital building control systems. Gira produces a range of switches as well as control, communication and security systems which are used in many parts of the world today.

Cycle time of less than one second

By using automation in high-volume areas, the company has always strived to optimize the efficiency of its production facilities, which are located in Germany. Gira‘s first assembly line, developed and designed in-house, was commissioned 60 years ago. The company first got in touch with STIWA more than ten years ago when it was looking for new, innovative production processes. However, another six years would pass before the time was right to launch a technology-oriented partnership.

“Our discussions with Gira have been highly target-oriented right from the start,” recalls Josef Pesendorfer, STIWA Engineer and project partner since the very beginning of the two companies’ collaboration: “For Gira, it was essential to achieve maximum system performance in combination with a wide range of types and minimum set-up times.” Consequently, the requirements for STIWA Engineering were high: in order to ensure controllable processes with cycle times of less than one second and a consistently high performance level over a long period of time, very close coordination with product development is required. The focus is thus on finding the right materials, achieving a large number of standardized components and optimizing the feeding technology.

Perfect team play

“We had access to Gira’s sample parts at all times in order to explore the entire spectrum of different procedures and process tests such as screwing, ultrasonic welding, testing, radial riveting tests or laser marking. Therefore, we were able to find ideal solutions along the entire process and could even stay well below the required cycle time,” says Josef Pesendorfer.

“Mutual support in all situations, even beyond the project level, has made our collaboration a great success,” adds Thomas Berger, Project Manager at STIWA Automation. “Our meetings were always characterized by a high level of mutual trust and full transparency. As a result, the products have undergone many optimizations and we have achieved several milestones in our efforts to expand automation even further.”

“Gira has relied on the ‚Made in Germany‘ label and Germany as a manufacturing location since 1905. With STIWA‘s innovative automation solutions, we are are able to maintain our international competitiveness for the future.”

Christian Feltgen, Managing Director Technology Gira

State-of-the-art and industry-leading systems

In mid-April 2022, STIWA delivered the first assembly system for sockets along with a suitable packaging system. Another system for socket outlet assembly followed a few weeks later. Finally, in May 2024, the third system for the fully automated assembly of designer switches was approved and commissioned. Series production has now started at full capacity - exactly as ordered, with maximum system performance and cycle times of well under a second in some cases. “You won’t find more sophisticated systems in the industry at the moment,” Christian Feltgen, Technology Director at Gira in Radevormwald, is convinced.

“You don’t find this kind of support to solve problems with many manufacturers. Gira and STIWA are entertaining a very trusting working relationship in which everyone can be sure that any challenges will be dealt with as a team.”

Heike Henze, Deputy Head of Procurement Gira