Gira: transparency is key

With ever larger and more complex production networks, transparency is an essential building block to achieve sustainable and efficient production…

Workpiece carrier logistics solved across manufacturers with AMS ZPoint-CI Workpiece Data Storage

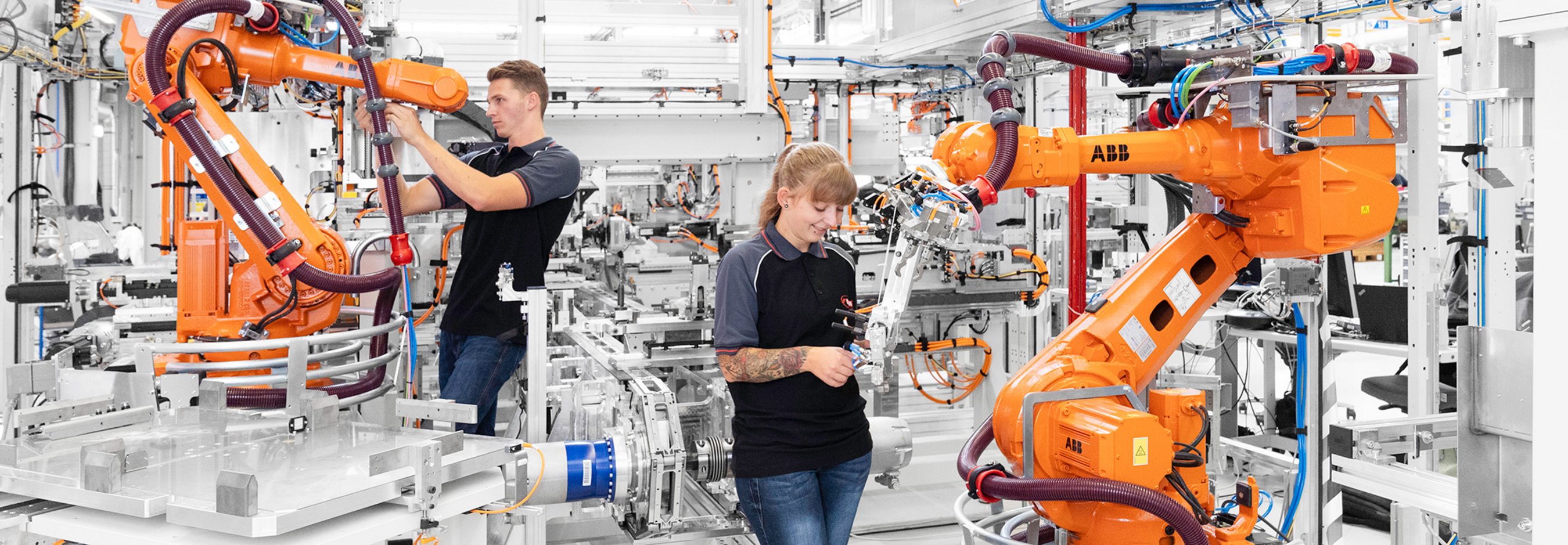

When an assembly line is made by different manufacturers, or when multiple products or components are assembled on one line, many challenges arise. Data integration of all plant components or adaptive, item-specific production of products often results in unplanned additional costs.

Machine builders can actively reduce complexity and manufacturing costs. Control technology and PLC programming are supported by standardised, field-proven solutions for establishing communication between plant components, for manufacturer-independent workpiece carrier logistics or for reworking.

"With the new, standardised, manufacturer-independent control station functions, we can support our partners even better in implementing complex scenarios in a cost-effective manner. We achieve this by extracting more and more logic from the PLC programs. This allows us to reduce project-specific effort," says Stephan Kriener, Head of Development.

With ever larger and more complex production networks, transparency is an essential building block to achieve sustainable and efficient production…

Mag. Alexander Meisinger, MSc

HEAD OF CUSTOMER SUCCESS MANAGEMENT