Transparency in the production process

Traceability is a key issue for many companies in the manufacturing industry. The cost of product recalls - in the automotive industry, for example - can run into the hundreds of millions. As a result, maintaining the highest quality standards and making effective use of existing data are increasingly becoming essential requirements for industry and demanding customers.

Data is already available on the shopfloor. The challenge is to collect this data reliably, to network it intelligently and to process it in such a way that meaningful analyses are possible.

STIWA Software supports you in establishing an evidence-based, continuous improvement process. With our tools you will not only ensure smooth operations and secure processes, but also the production of products of the highest quality. We help you to realise the full potential of your production.

This is your benefit

Transparent traceability

- Accurate tracking of produced parts

- Capture, network and analyse product and process data, measurement curves, images, acoustic tests and more

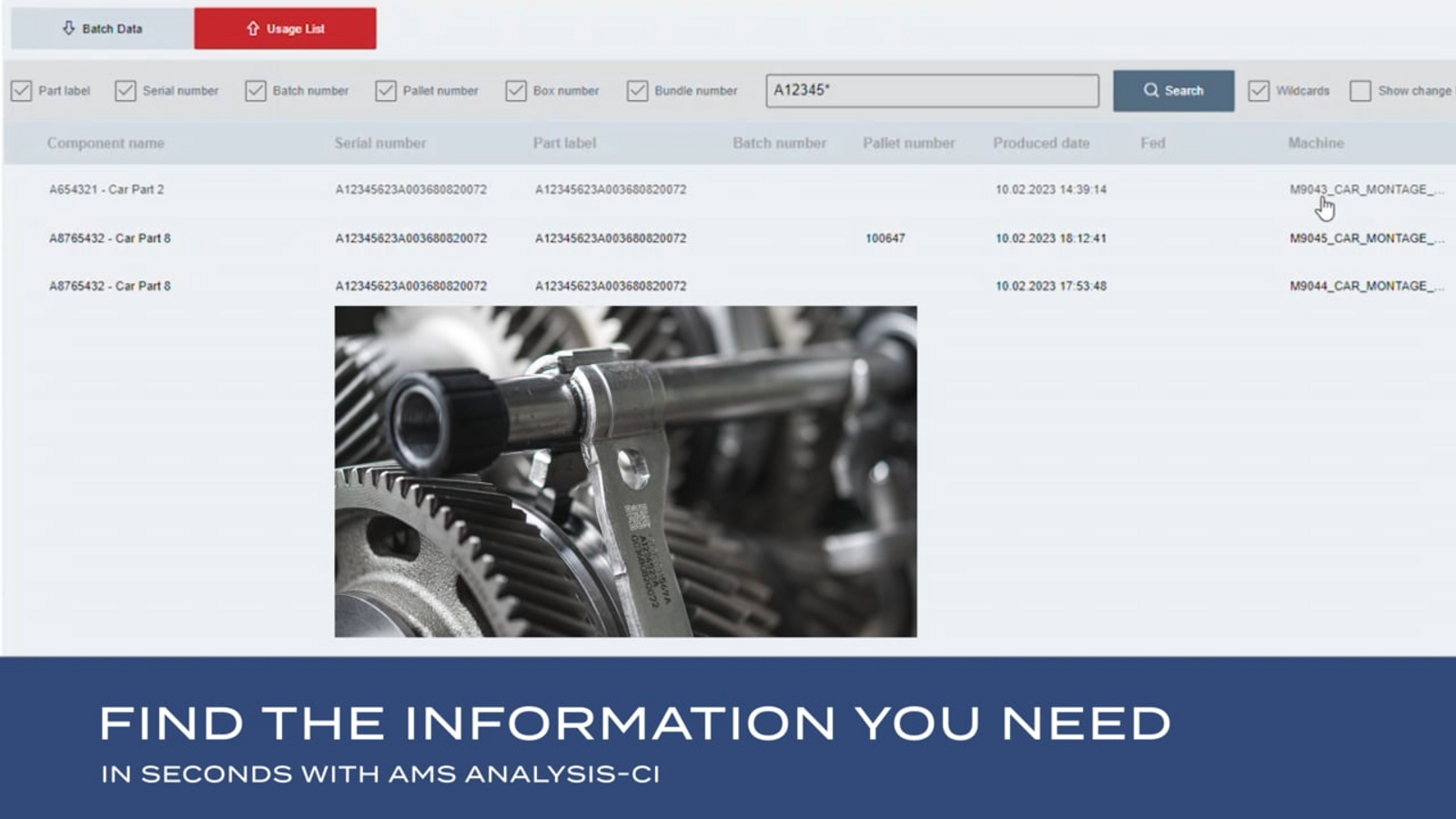

- Find the information you need in seconds

- Limit the number of parts to be recalled when a recall is imminent

- Save costs

Upstream Tracing

Upstream tracing refers to traceability from the end product - through batches (e.g. coils) or the earliest stages of production or procurement - to individual parts.

The focus is on tracking the processes, materials, suppliers and other relevant factors involved in the manufacture of a product.

Downstream Tracing

Downstream tracing allows materials, precursors and information to be tracked along the production chain. The process traces the path from individual parts, batches, materials, pallet numbers, transport units and orders to the finished product.

This enables companies to maintain control of quality, minimise risks (e.g. recalls), comply with regulations and other factors right through to the final step of the manufacturing process.

Mag. Alexander Meisinger, MSc

HEAD OF CUSTOMER SUCCESS MANAGEMENT